Cardboard Box Making Machine

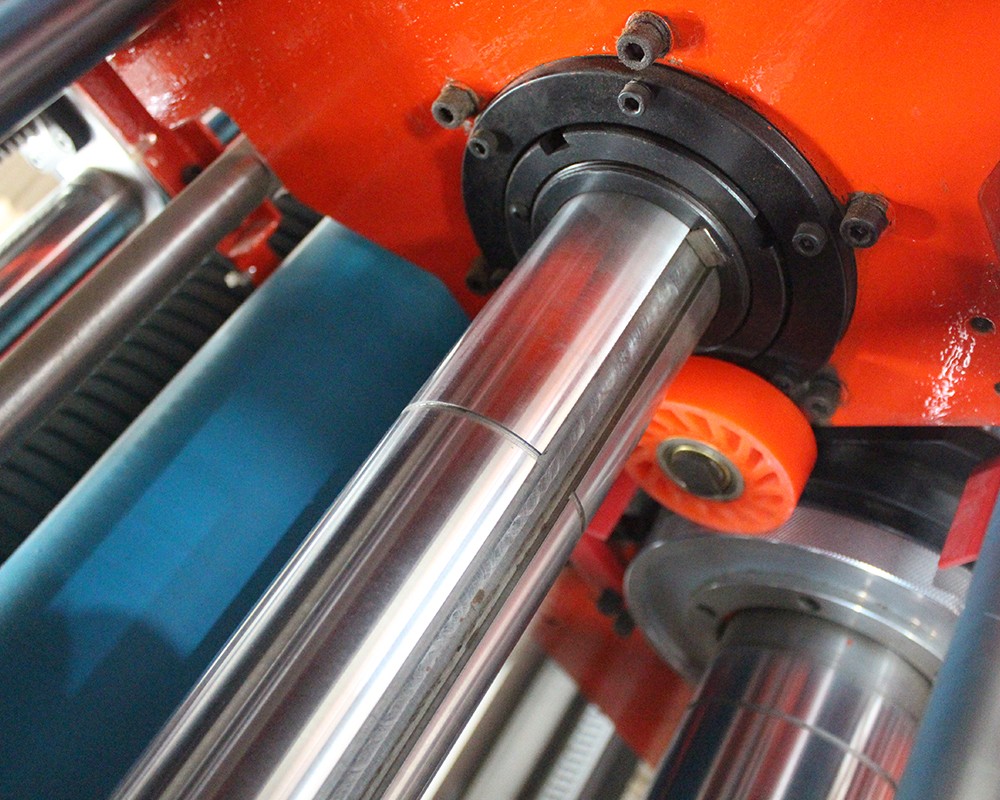

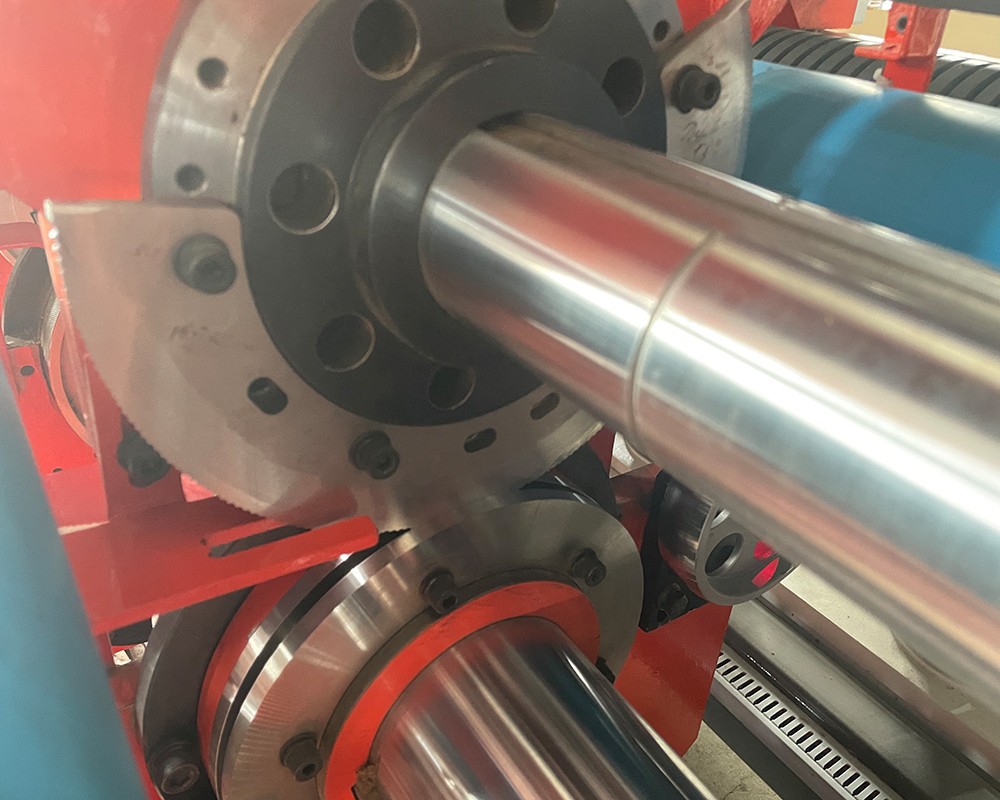

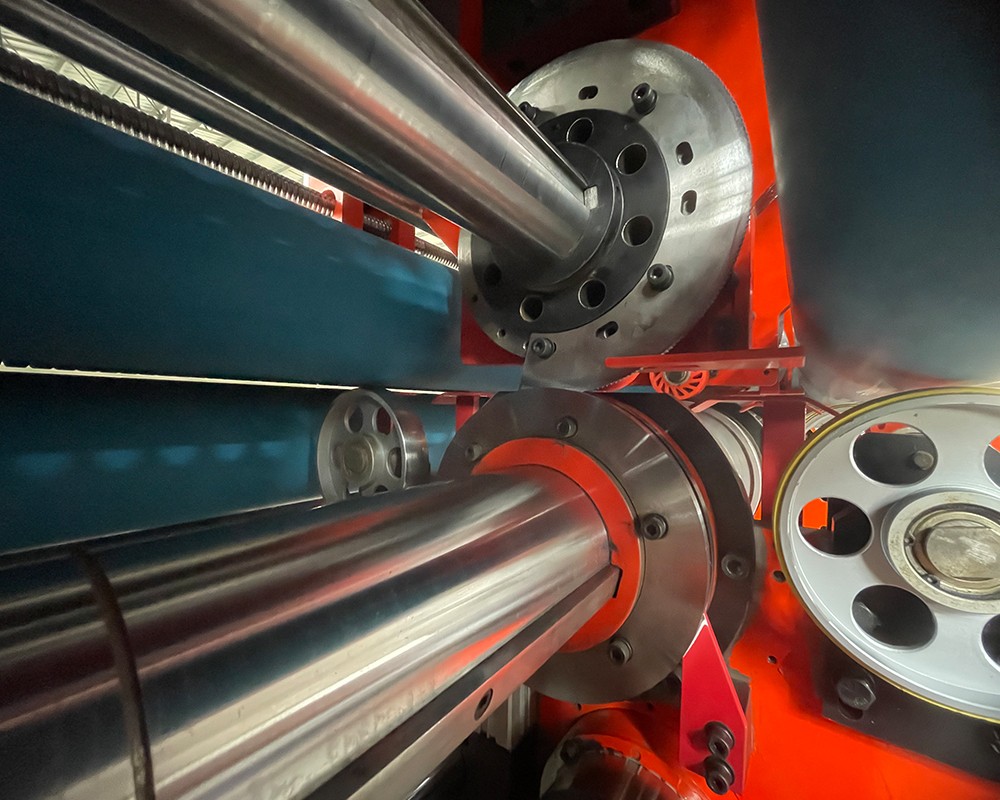

Auto Rotary Slotter Machine

-

+86-13702592807 WhatsApp

-

sales@jingoupack.com Email

Carton making machines process cardboard materials into cartons of various sizes and specifications through a series of automated processes. These cartons are widely used in packaging, logistics, warehousing and other fields to protect goods and facilitate transportation and storage. Carton making machines are characterized by high efficiency, precision and high degree of automation, and are indispensable equipment in the modern packaging industry.

Parameter

| Model | RS-25 | UNIT |

| Max.feeding Size | 2500xunlimited | MM |

| Min Cutting Size | 250×600(LxW) | MM |

| Max.slotting Depth | 450 | MM |

| Slotting Width | 7 | MM |

| Feeding Thickness | 2~11 | MM |

| 02omaxbox Height | No Limit | MN |

| 02xo Min Box Height | 120 | MM |

| Min Slotting Gad | 220×60×220×60 | MM |

| Maxanglecutting Width | 45 | MM |

| Total Motorpower | Abt15 | K |

| Dimension(L*W*H) | Abt 1650x4100x1650 | MM |

| Overall Weight | Abt 5200 | KG |

Main types

Semi-automatic carton making machines: manual assistance is required to complete some operations, such as cardboard conveying, cutting size adjustment, etc. This type of machine is suitable for small and medium-sized production or sample production.

Fully automatic carton making machines: fully automated production, from cardboard conveying, cutting, forming to output of finished products, the entire process does not require manual intervention. This type of machine is suitable for large-scale production, which can greatly improve production efficiency and reduce costs.

Multifunctional carton making machines: In addition to the basic carton making functions, it also has additional functions such as printing, creasing, and slotting. This type of machine can meet more diverse production needs and increase the added value of products.

Working principle

Cardboard conveying: The cardboard material is fed into the machine through a conveying device. The conveying device usually adopts a transmission method such as a chain or belt to ensure smooth and continuous conveying of the cardboard.

Cutting and forming: The cardboard is cut into the required size and shape by the cutting device, and then the cut cardboard is folded and glued by the forming device to form the basic structure of the carton. The cutting device usually uses cutting methods such as blades or lasers, and the forming device forms the carton through molds or pressure wheels.

Output and sorting: The finished carton is output through the output device, and sorted, stacked, etc. The output device usually uses a conveyor belt or slide to ensure that the carton can be output smoothly and orderly.

Performance characteristics

High efficiency: The carton making machine has efficient production capacity and can quickly complete the production tasks of a large number of cartons.

Accuracy: The use of advanced cutting and forming technology can ensure that the size and shape of the carton are accurate.

High degree of automation: The fully automatic carton making machine can realize the whole process of automated production from cardboard conveying, cutting, forming to outputting finished products, reducing manual intervention and improving production efficiency.

Versatility: Some carton making machines also have additional functions such as printing, creasing, and slotting, which can meet more diverse production needs.

Easy to operate and maintain: Carton making machines usually use control systems such as touch screens or PLCs, which are simple and easy to understand. At the same time, the machine's structural design is reasonable and easy to maintain and maintain.

Application fields

Carton making machines are widely used in packaging, logistics, warehousing and other fields. In the packaging industry, carton making machines provide reliable packaging solutions for various commodities;

In the logistics industry, carton making machines facilitate the transportation and storage of commodities;

In the warehousing industry, carton making machines are used to protect commodities from damage or contamination.

Purchase suggestions

Production needs: Choose the appropriate type of carton making machine according to your own production needs, such as semi-automatic, fully automatic or multi-functional.

Machine performance: Pay attention to the machine's production efficiency, cutting accuracy, degree of automation and other performance indicators to ensure that it can meet production requirements.

After-sales service: Choose a supplier with good after-sales service to ensure timely technical support and maintenance services during use.

Price factors: Under the premise of ensuring performance and quality, consider the price factor of the machine and choose a product with high cost performance.

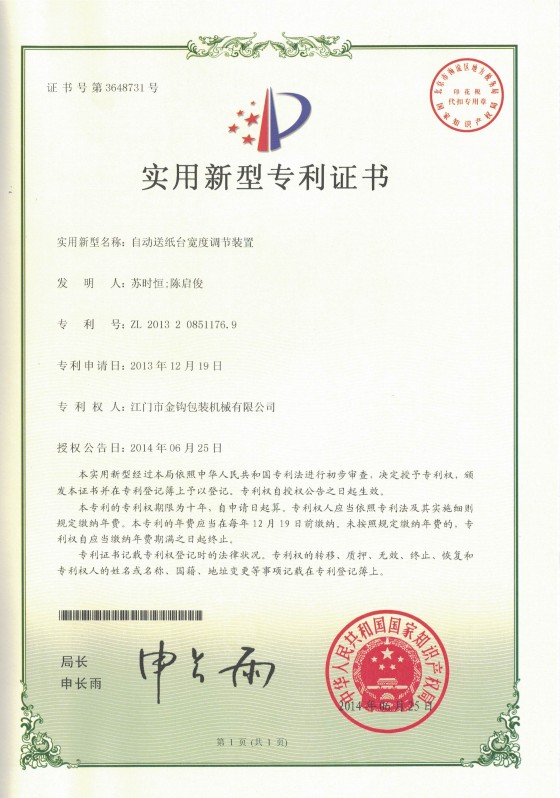

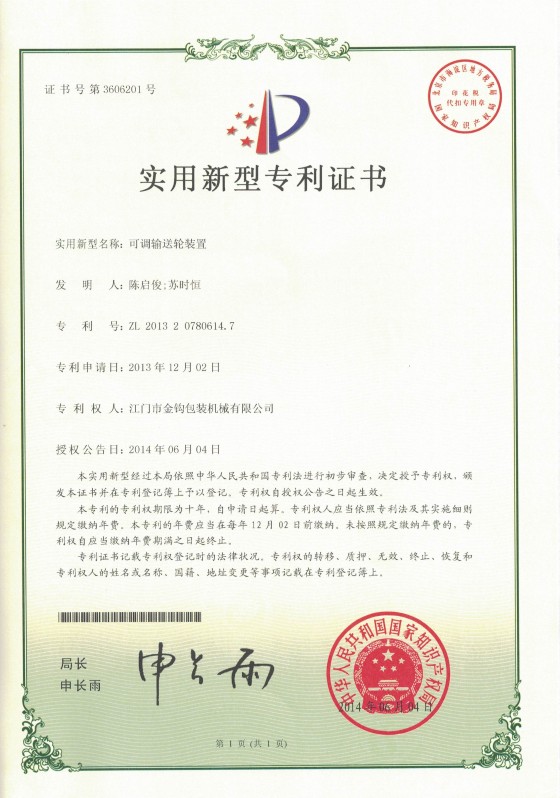

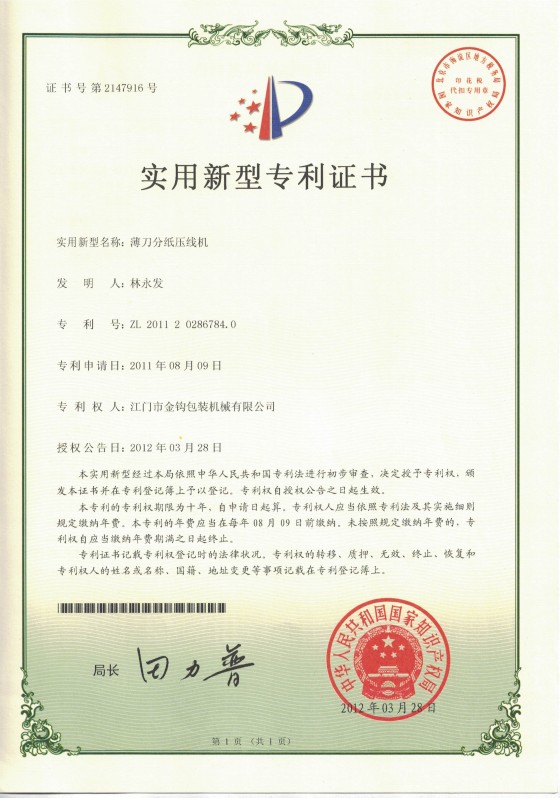

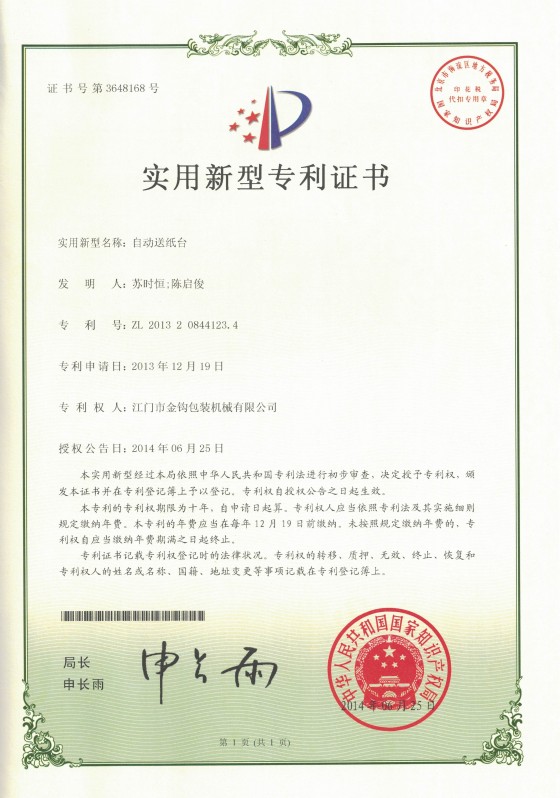

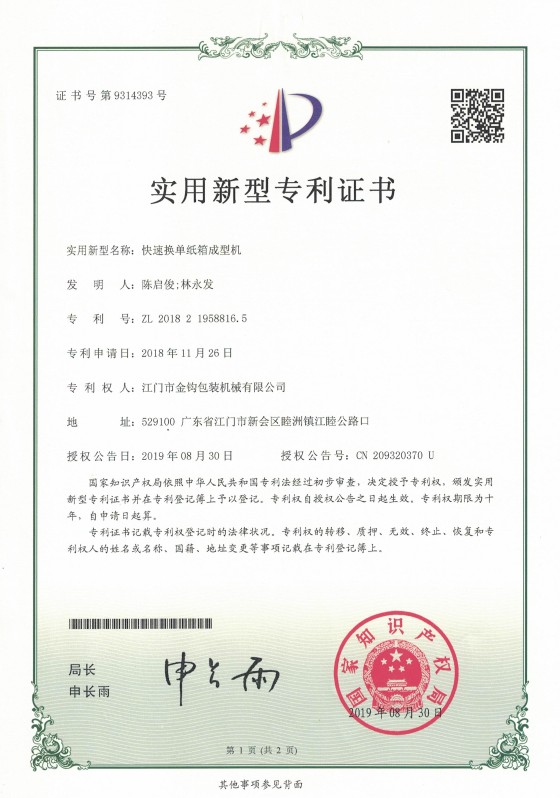

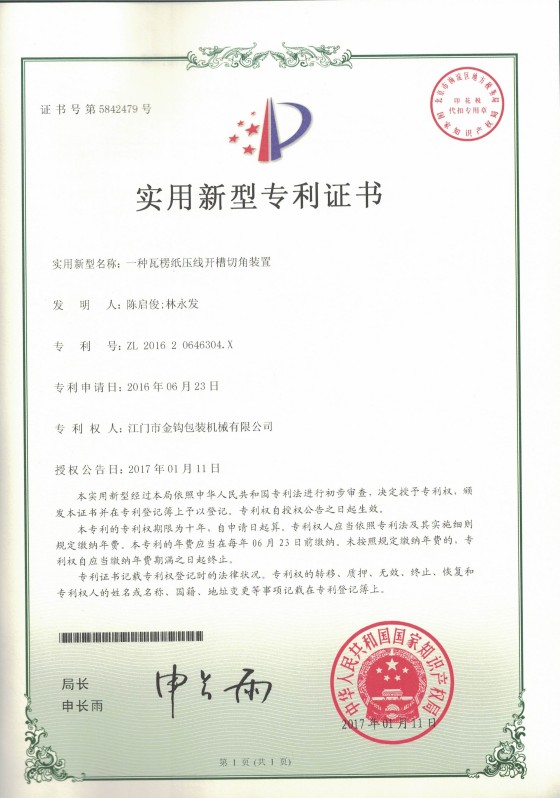

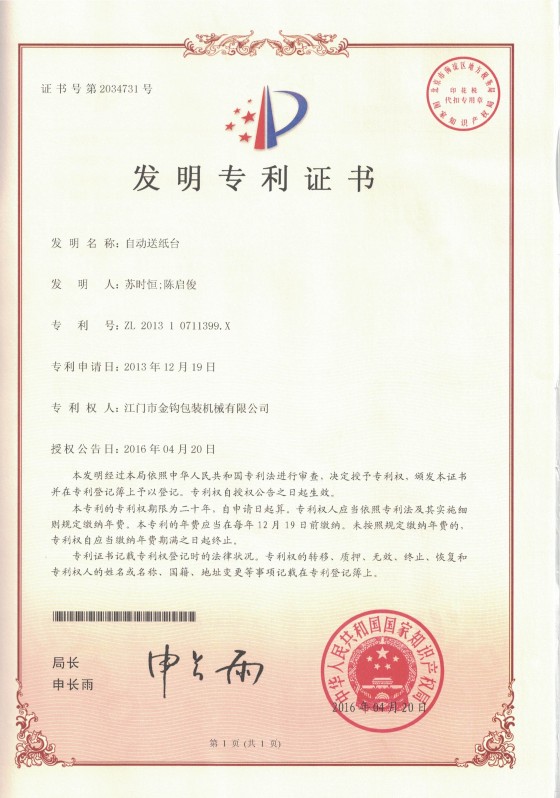

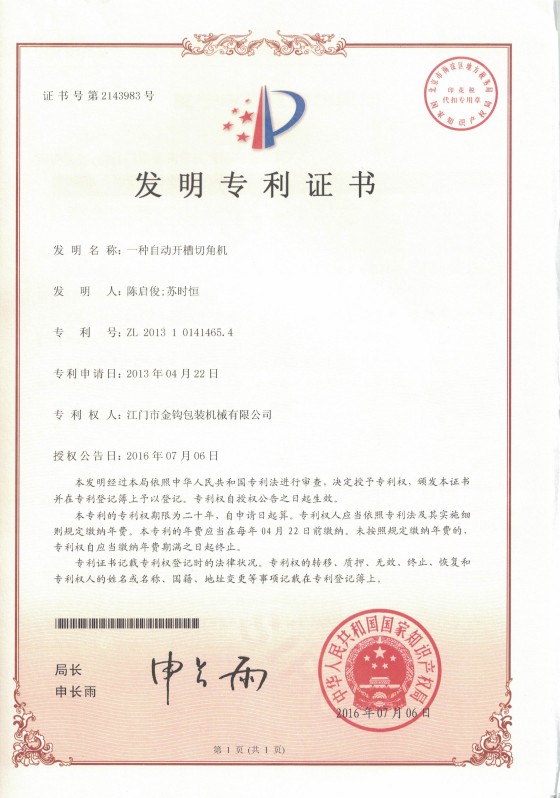

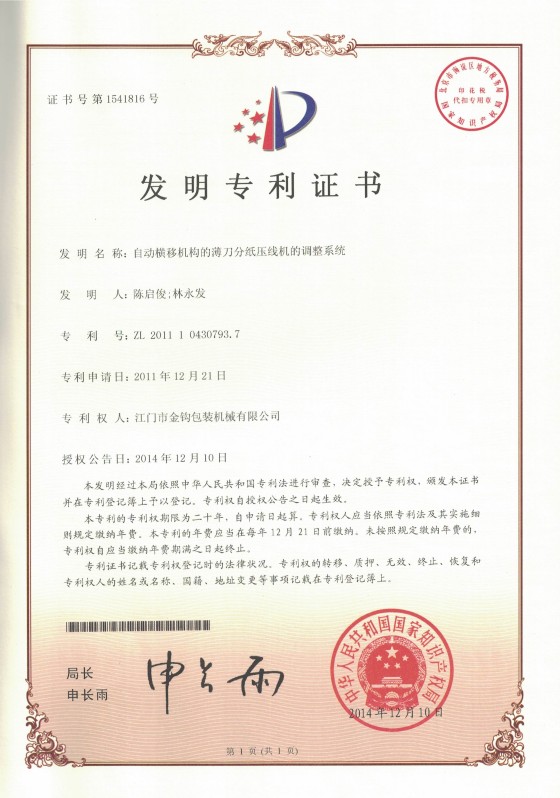

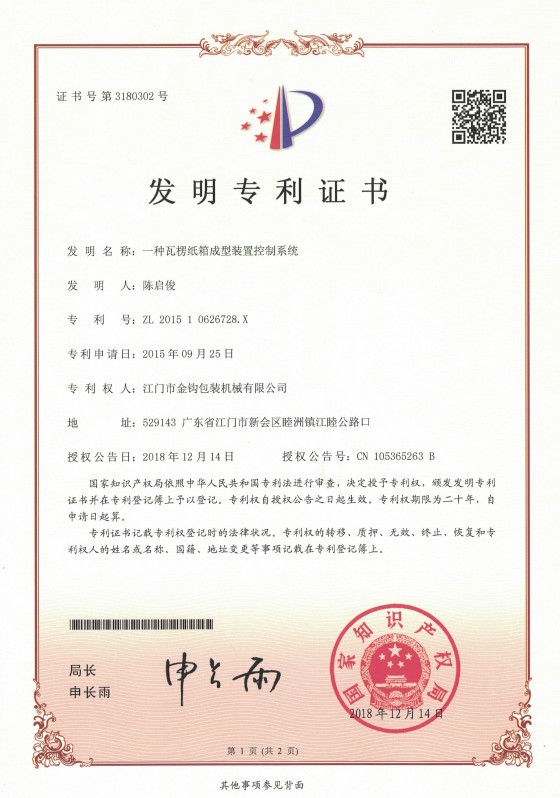

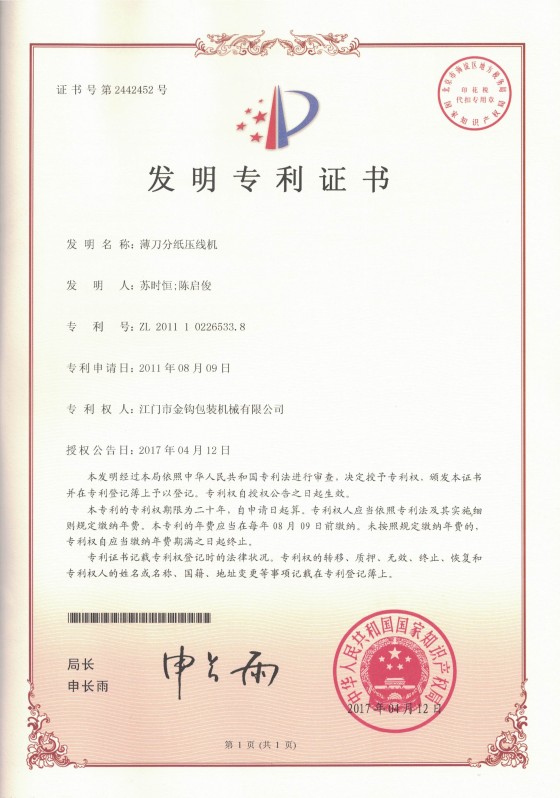

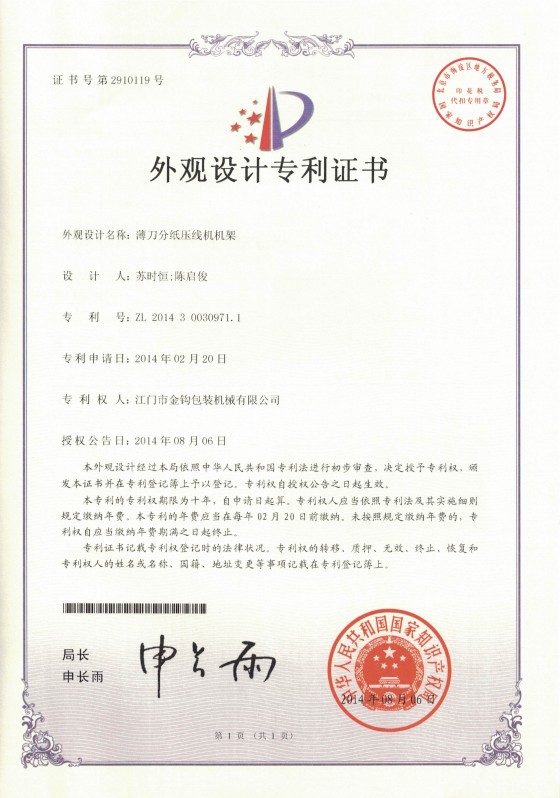

Jingou packaging machinery Co.,ltd

Jingou is a high-tech enterprise with forward thinking special designed,manufacturer of corrugated carton machine for small quantity orders .We had developed a very first auto thin slitter scorer machine which you can not find all over the world in 2009.And we keep working on developing functional box maker machine CK25 which earn many invention patents and utility model patents and passed CE certifications .Jingou machine had completed changed the low efficiency production mode of small quantity orders to meet the true needs of customers .