Cardboard Machine

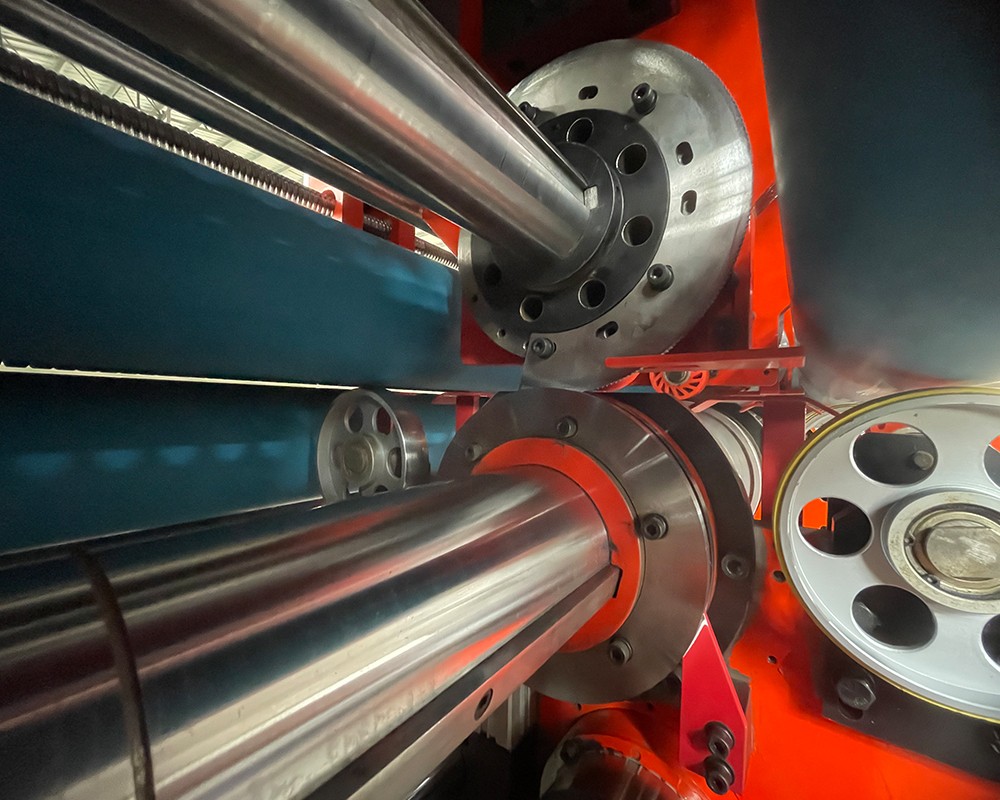

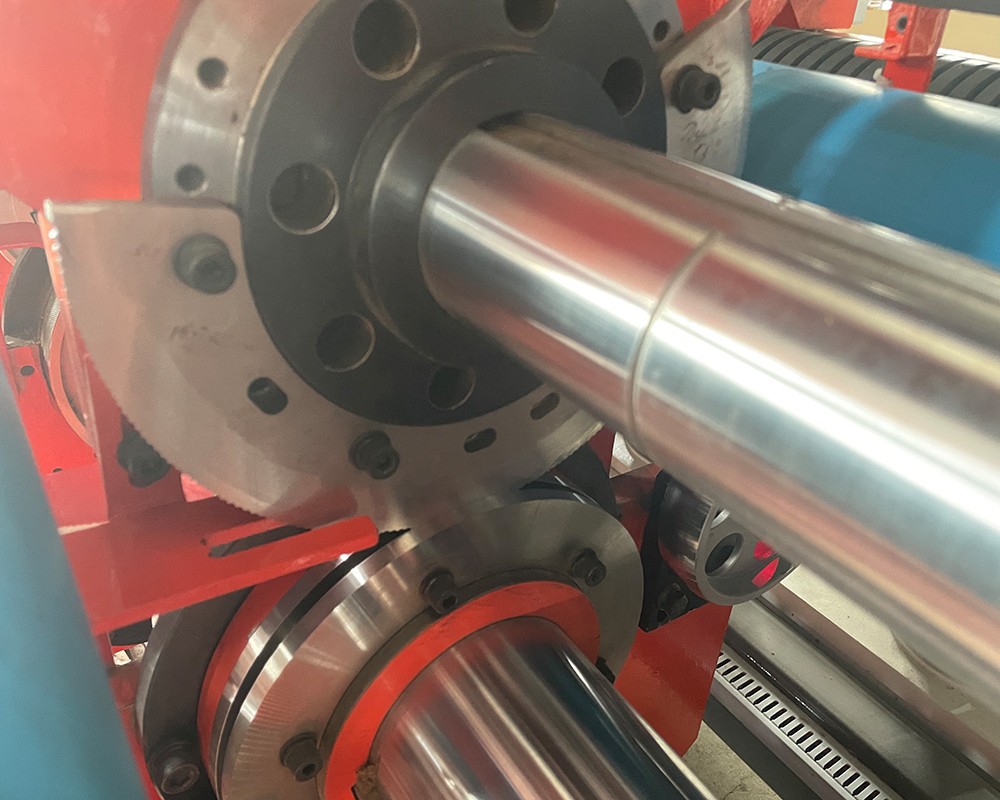

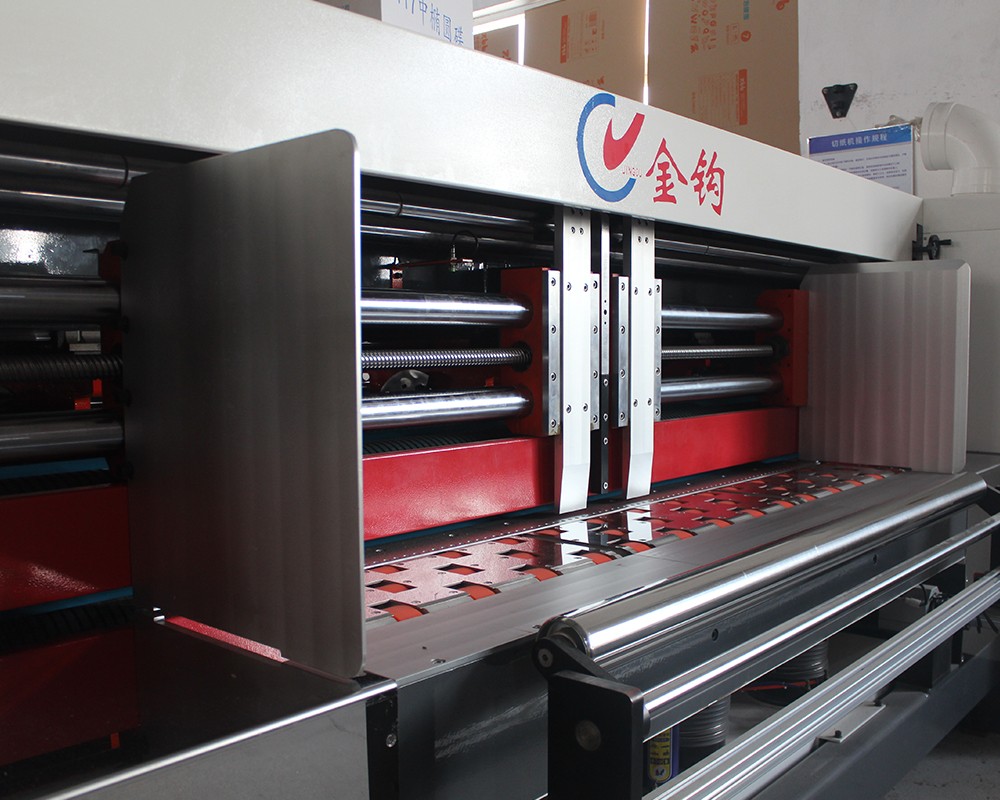

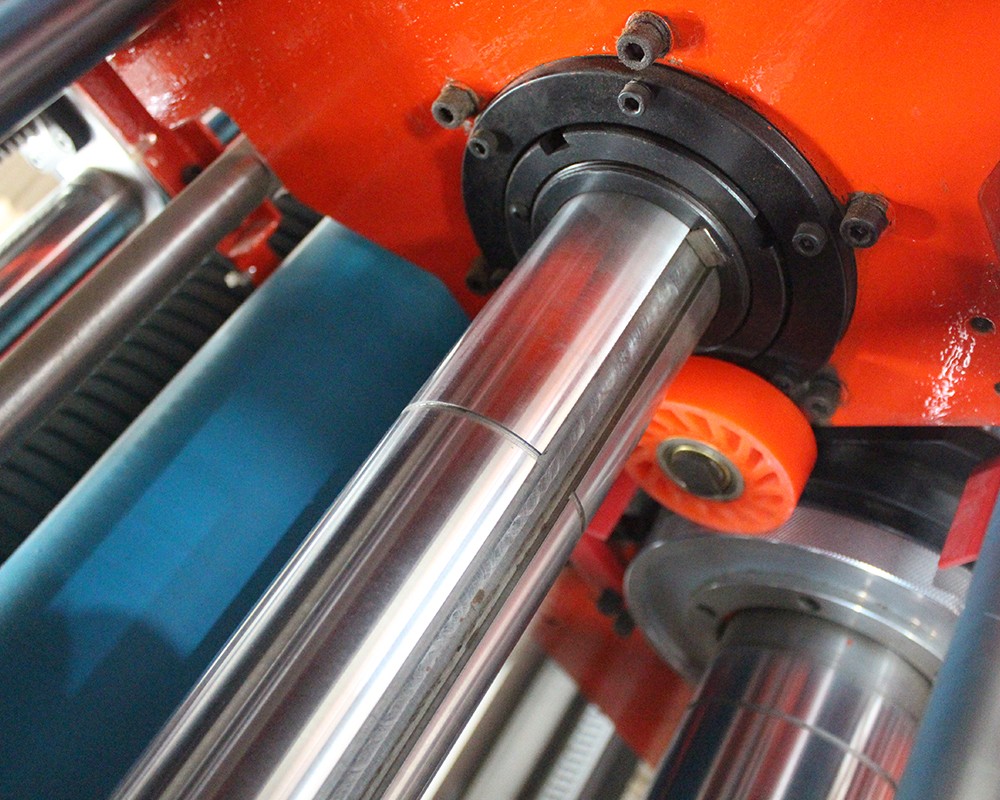

Auto Rotary Slotter Machine

-

+86-13702592807 WhatsApp

-

sales@jingoupack.com Email

"cardboard machine" usually refers to machines and equipment related to cardboard. Such machines and equipment have a wide range of applications in many fields, including but not limited to packaging, printing, manufacturing and prototyping.

Rotary Slotting Machine Parameter

| Model | RS-25 | UNIT |

| Max.feeding Size | 2500xunlimited | MM |

| Min Cutting Size | 250×600(LxW) | MM |

| Max.slotting Depth | 450 | MM |

| Slotting Width | 7 | MM |

| Feeding Thickness | 2~11 | MM |

| 02omaxbox Height | No Limit | MN |

| 02xo Min Box Height | 120 | MM |

| Min Slotting Gad | 220×60×220×60 | MM |

| Maxanglecutting Width | 45 | MM |

| Total Motorpower | Abt15 | K |

| Dimension(L*W*H) | Abt 1650x4100x1650 | MM |

| Overall Weight | Abt 5200 | KG |

Types and Applications

Cardboard Cutting Machine

Function: Used to cut cardboard and process it into parts or products of the required size and shape.

Application: Packaging industry, hand-made, prototyping, etc.

Cardboard Gasket Molding Machine

Function: Automatically fold and paste the inner liner of the cardboard box to provide additional protection or support for the cardboard box or paper box.

Application: Packaging industry, logistics industry, etc.

Cardboard Molding Machine

Function: Process cardboard into various three-dimensional shapes, such as boxes, pallets, etc.

Application: Packaging, transportation, storage and other fields.

Cardboard Printing Machine

Function: Print patterns, text and other information on cardboard.

Application: Packaging industry, advertising industry, etc.

Features and Advantages

Efficiency: Cardboard machines usually have efficient production capacity and can quickly complete a large number of cardboard processing tasks.

Precision: The use of advanced cutting, forming and printing technologies can ensure that the size, shape and printing quality of the cardboard are accurate.

High degree of automation: Many cardboard machines are equipped with automated control systems, which can realize the full process of automated production from cardboard conveying, processing to finished product output.

Versatility: Some cardboard machines also have a variety of additional functions, such as creasing, slotting, bonding, etc., which can meet more diverse production needs.

Environmental protection: As a recyclable material, the use of cardboard machines helps to reduce the use of non-degradable materials such as plastics, which meets environmental protection requirements.

Purchase and maintenance

Purchase suggestions

Choose the appropriate cardboard machine type according to production needs.

Pay attention to the machine's production efficiency, cutting accuracy, degree of automation and other performance indicators.

Choose a supplier with good after-sales service and maintenance support.

Maintenance suggestions

Clean and maintain the cardboard machine regularly to ensure that the machine is in good working condition.

Follow the operating procedures to avoid improper operation that causes machine damage or failure.

Replace worn parts and consumables in time to ensure the stability and reliability of the machine.

In summary, "cardboard machine" covers a variety of cardboard-related machines and equipment, which play an important role in packaging, printing, manufacturing and prototyping. When purchasing and using cardboard machines, it is necessary to fully consider factors such as production needs, performance indicators, after-sales service and maintenance.

Jingou packaging machinery Co.,ltd

Jingou is a high-tech enterprise with forward thinking special designed,manufacturer of corrugated carton machine for small quantity orders .We had developed a very first auto thin slitter scorer machine which you can not find all over the world in 2009.And we keep working on developing functional box maker machine CK25 which earn many invention patents and utility model patents and passed CE certifications .Jingou machine had completed changed the low efficiency production mode of small quantity orders to meet the true needs of customers .