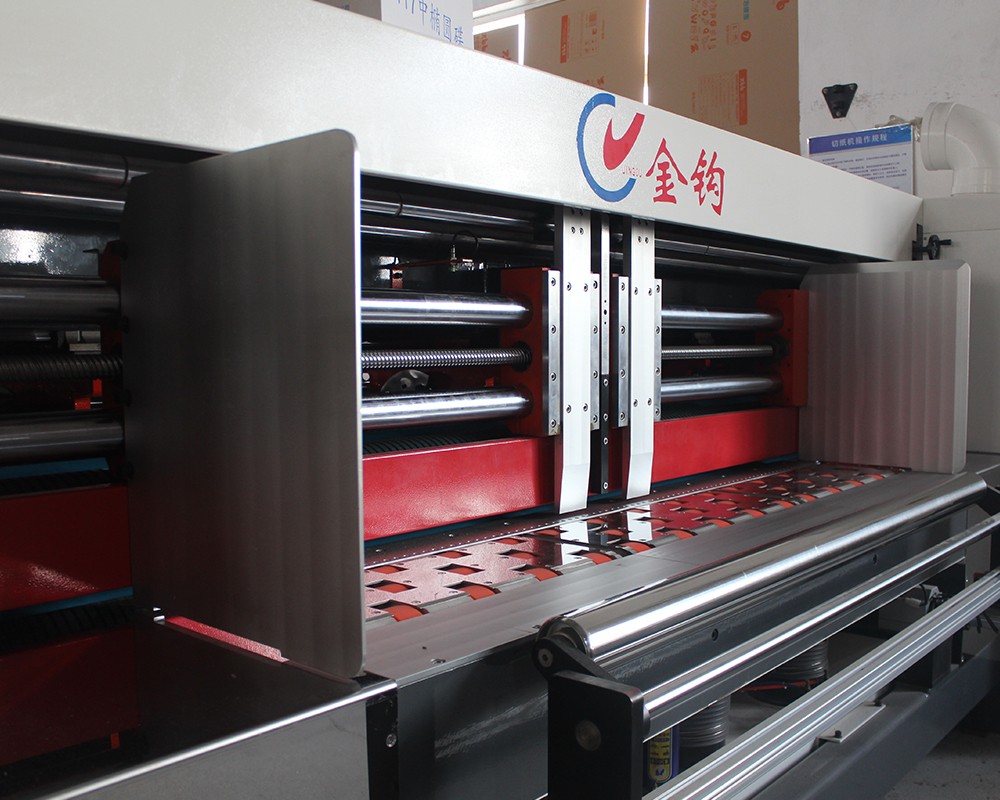

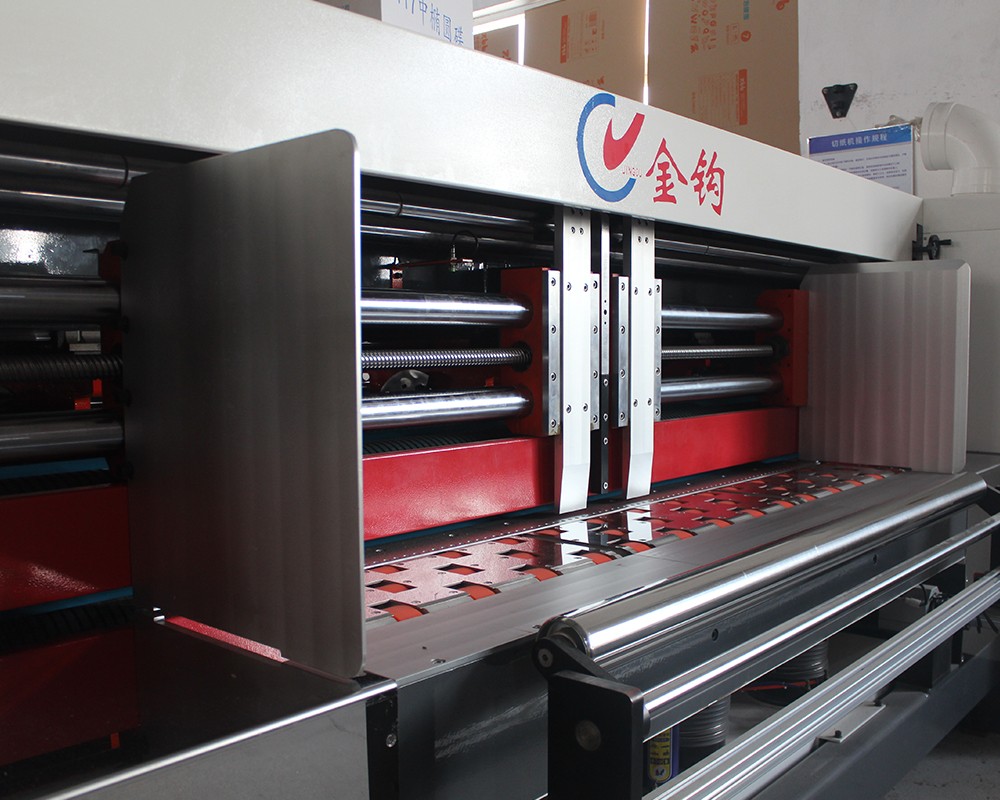

Auto Rotary Slotter Machine

Auto Rotary Slotter Machine

-

+86-13702592807 WhatsApp

-

sales@jingoupack.com Email

The Automatic Rotary Slotting and Creasing Machine is simply the most technologically advanced way to mass produce corrugated boxes with precision. This advanced equipment is manufactured by a prominent China rotary slotting machine factory which integrates rotary slotting with creasing in one system. Which delivers accurate cuts, and creases and operates seamlessly making it quite popular among rotary slotting machine suppliers and manufacturers across the globe.

rotary slotting machine Parameter

| Model | RS-25 | UNIT |

| Max.feeding Size | 2500xunlimited | MM |

| Min Cutting Size | 250×600(LxW) | MM |

| Max.slotting Depth | 450 | MM |

| Slotting Width | 7 | MM |

| Feeding Thickness | 2~11 | MM |

| 02omaxbox Height | No Limit | MN |

| 02xo Min Box Height | 120 | MM |

| Min Slotting Gad | 220×60×220×60 | MM |

| Maxanglecutting Width | 45 | MM |

| Total Motorpower | Abt15 | K |

| Dimension(L*W*H) | Abt 1650x4100x1650 | MM |

| Overall Weight | Abt 5200 | KG |

Advantages of Rotary Slotting Machine

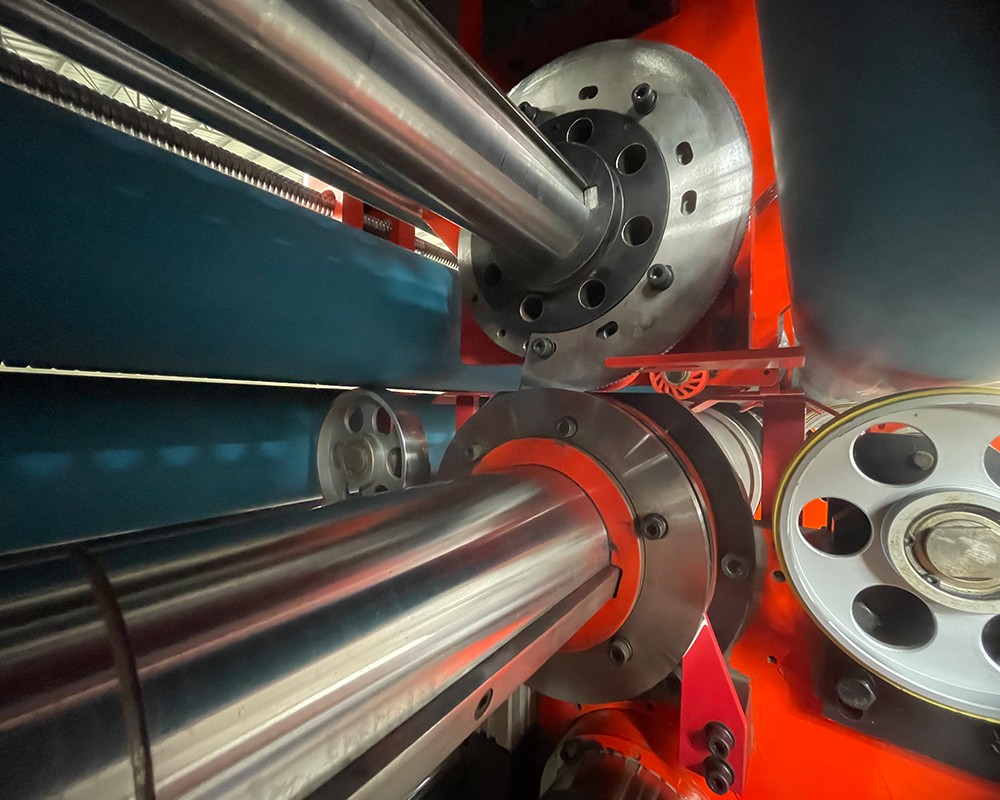

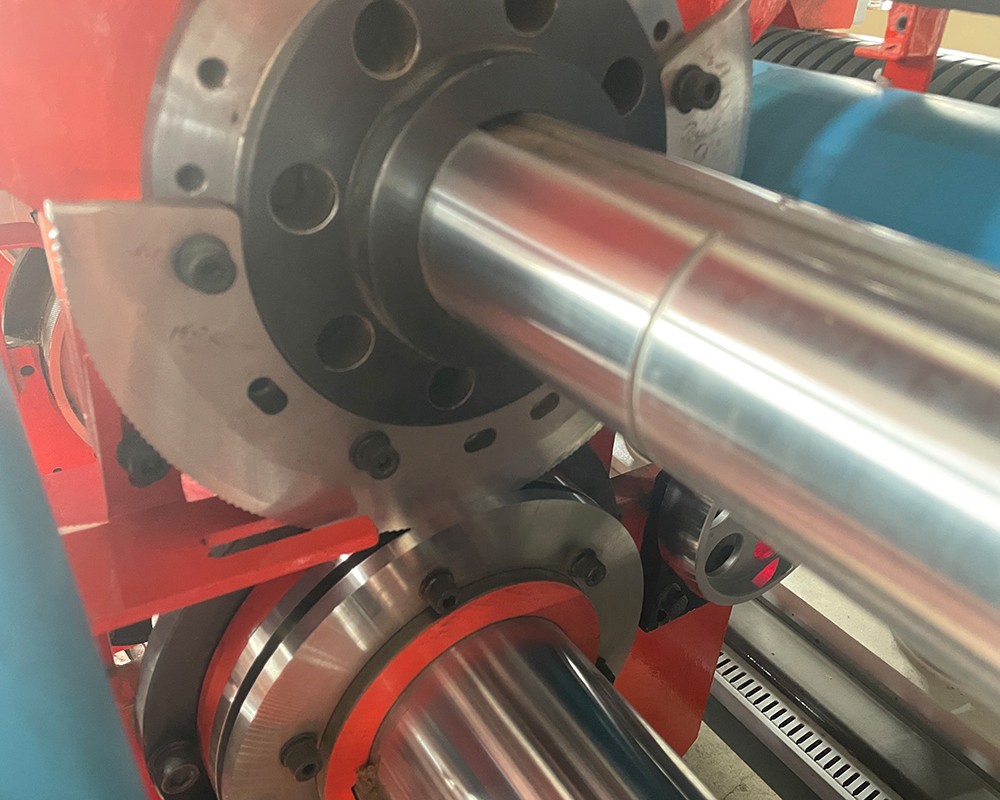

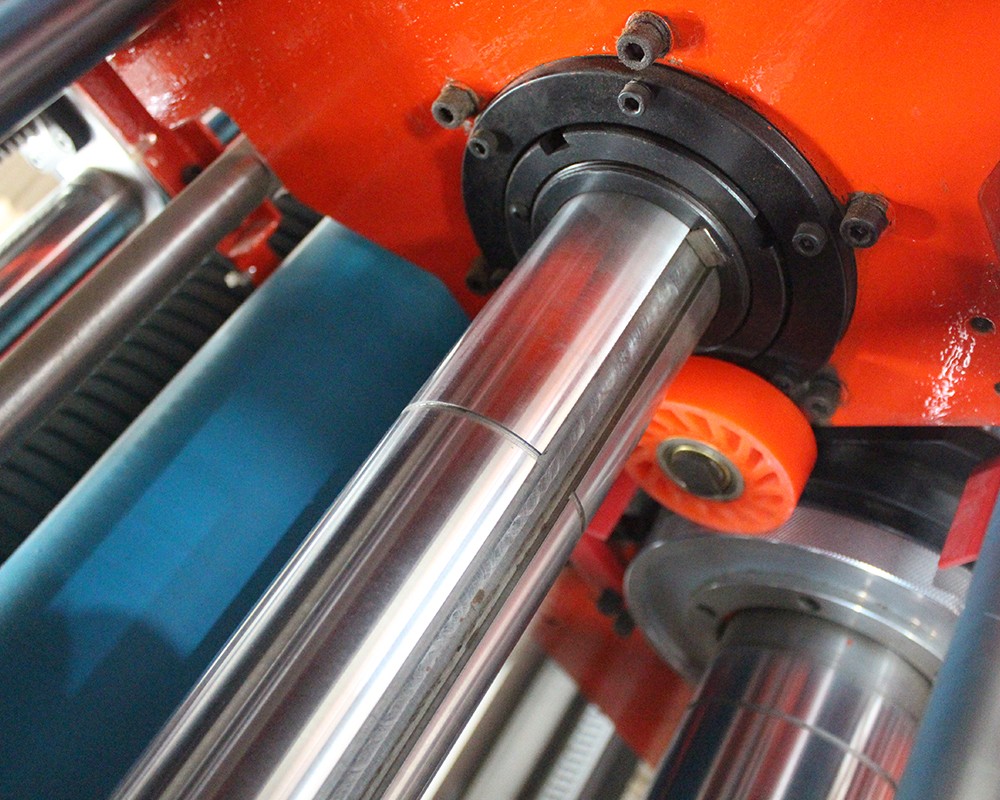

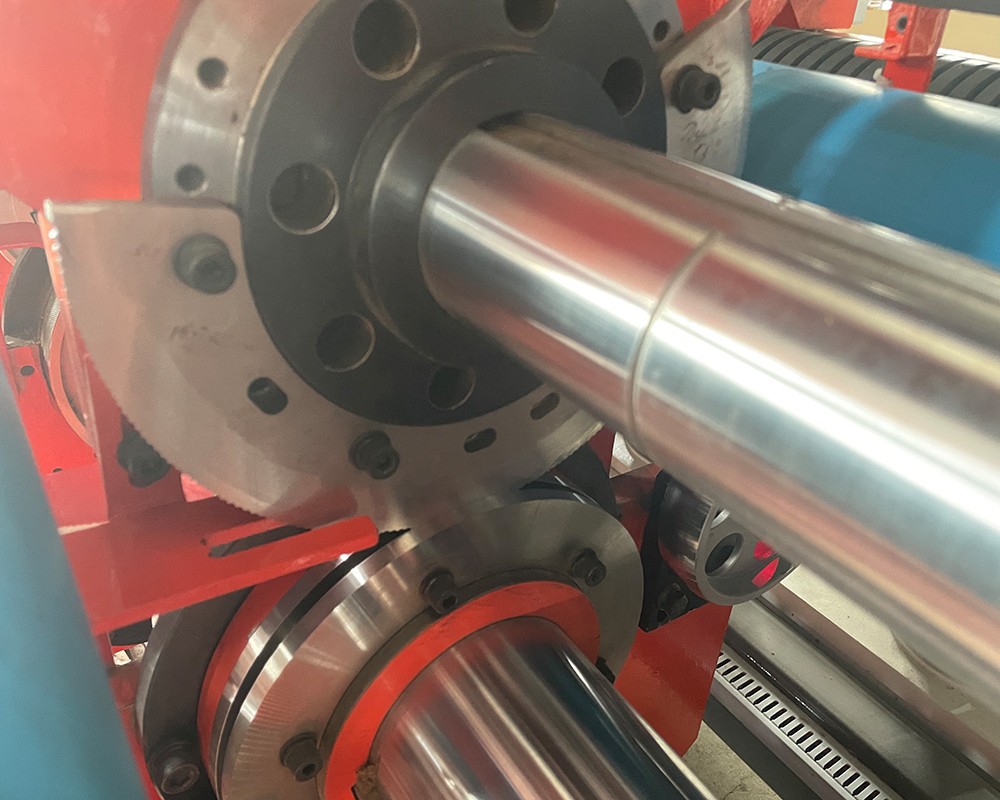

Precision Engineering:

Features digitized controls and a servo motor for corrugated paper slotting with high accuracy.

Allows users to control box height and the depth of the slots independently from each other.

Efficiency and Automation:

Fully automated. Stores 300 orders in memory, helps reduce time in setting up when switching between orders.

Faster production runs are ensured by ensuring that easy adjustments are made to the production run parameters.

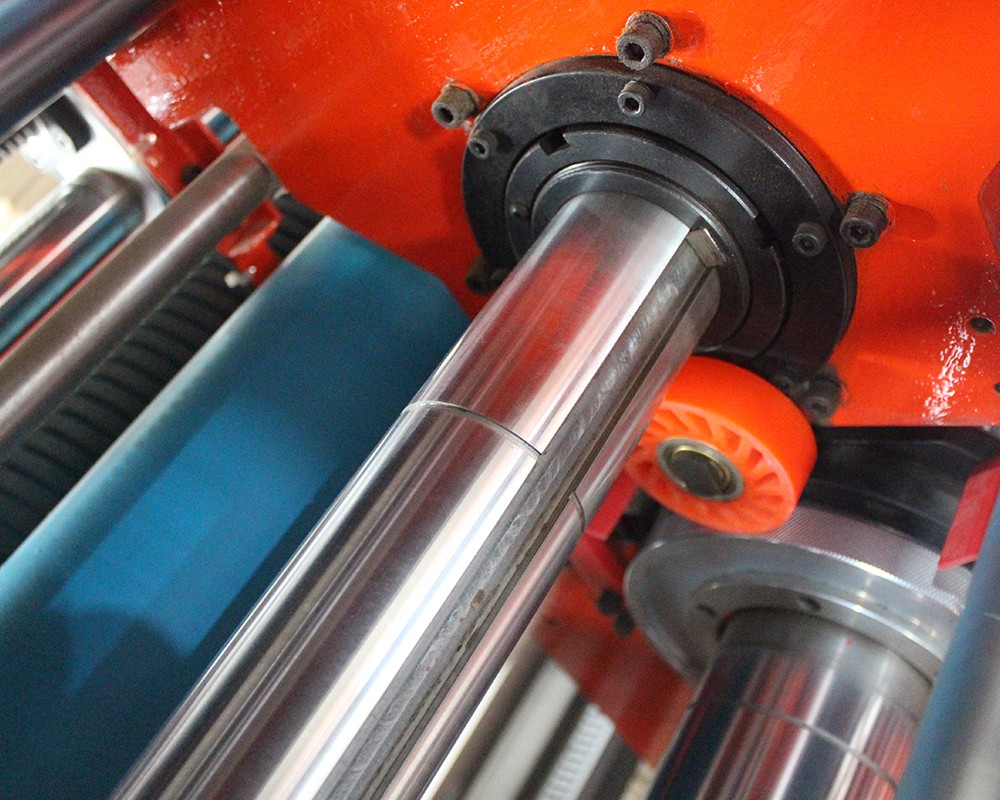

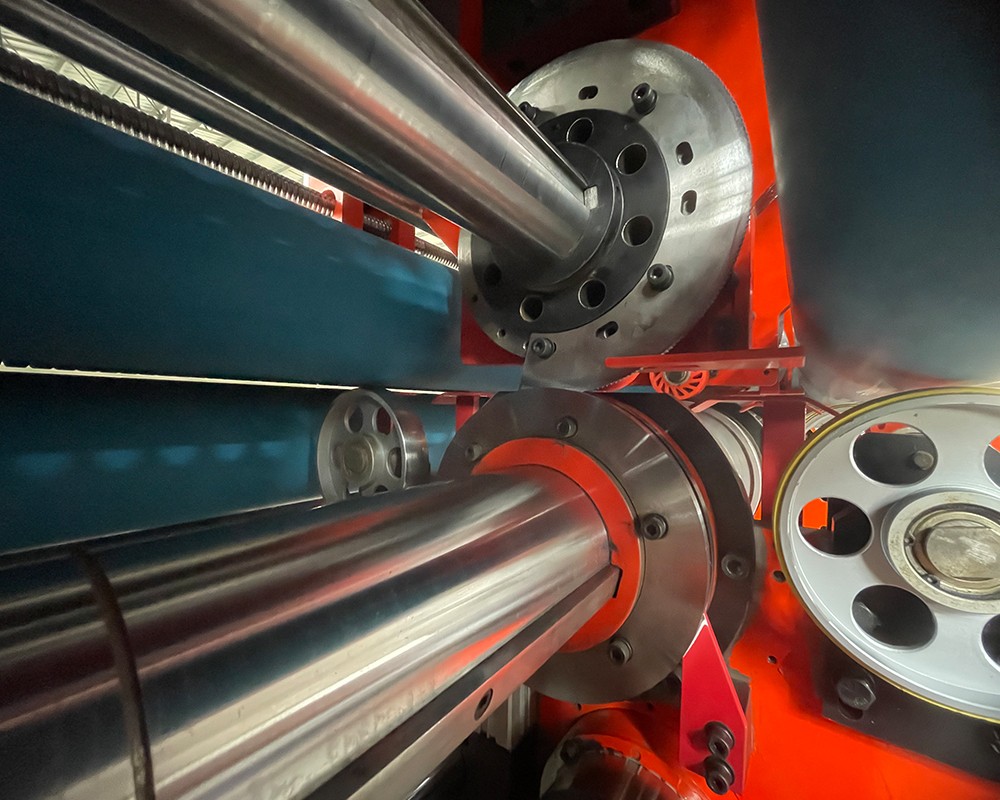

Durability and Versatility:

Designed to work with different thicknesses of corrugated board (2-11 mm).

Capable of creating all types of box sizes from large sized cartons to intricate small boxes for packaging.

User-Friendly Interface:

Has a touchscreen control for easy and quick operation of the machine.

Designed in a way that first time users can simply air the machine without causing any risk in the workplace.

Energy Efficiency:

Energy consumption is minimized thanks to the optimized independent slotting model.

Application of Rotary Slotting Machine

Corrugated Box Manufacturing:

Ideal for high volumes production of corrugated boxes that require slotting and creasing features.

Industrial Packaging:

Commonly needed in businesses that call for tough and tailor made packages.

Printing and Packaging Factories:

To complement the fully automated production systems, Chinese rotary slotting machine suppliers prefer these slotters.

Rotary Slotting Machine FAQs

Q1. What is the basic purpose of using rotary slotting machine?

A1. The machine combines slotting and creasing functions, thus, enabling precise cuts and folds in the manufacture of quality corrugated boxes.

Q2. What are the benefits of using this machine instead of other machines?

A2. This automatic rotary slotting machine is accurate, has fast production index, and, energy efficiency in production. These features of memory storage and digital control distinguish it from other players.

Q3. Can this machine be used for small factories?

A3. Yes, it can be tailored to suit small and large-scale production settings, therefore making it very applicable in different scenarios.

Q4. Why would one want to a Chinese rotary slotting machine manufacturer?

A4. Competitively priced because of the sturdy Chinese designs and innovative technologies, these manufacturers are without doubt the preferred choice of customer worldwide.

Q5. What blade adjustments does this machine work within?

There is no requirement for human intervention during blade adjustments since this process is fully automated, as it has already been discussed above.

What is a Rotary Slotting Machine?

Rotary slotting machine is one of the machines which carries out the operation of making corrugated boxes. It carries out the operations of slotting out rectangular slots which are cut into sheet of corrugated material as well as creasing fold lines on the sheet so that boxes can be easily assembled. These machines also utilize rotary blades and creasers to effect a cut and fold with precision. These machines are important for packaging industries as they act as an essential tool in the manufacturing process. Most of these devices exhibit high speed, accuracy, versatility in the sizes and thicknesses of corrugated boards that they can process.

Specific Rotary Slotting Machines

Manual Rotary Slotting Machines

Features: These are very basic and cheap machines that do not have powered creasing or blade adjustment features and require the personnel to do these adjustments.

Advantages: Relatively low cost and appropriate for lower production scale.

Applications: Geared best towards small packaging workshops or short production runs.

Semi-Automatic Rotary Slotting Machines

Features: Incorporates some level of automation for setting blades and memorizing order but there where manual adjustment is still needed for some features.

Advantages: Quicker and more efficient than manual machines but also caters for moderate production demand.

Applications: Suitable for medium size plants engaged in corrugated box production.

Automatic Rotary Slotting Machines

Features: Fully controlled by PLC, HMI, and automatic blade and creasing order adjustment with the previous memory order of the production.

Advantages: Capable of making very precise measurements, efficient and can work in large quantities.

Applications: Suited for mass production factories that deal with packaging but require speed of high margins.

Thin Blade Rotary Slotting Machines

Features: Employs the use of thin tungsten-carbide blades that give smoother and cleaner cuts which comfortably reduces fiber damage and quality of the slots and the creases.

Advantages: Great for high end packaging as they are very useful in cases where accuracy and a lot of cardboard integrity has to be maintained.

Applications: Companies that are more keen on offering high end packaging solution s who prefer these.

Combined Rotary Slotting and Creasing Machines

Features: Gives you a stage where the slitting and creasing process takes place together which minimizes the need for two individual machines.

Advantages: It makes van loads more efficient, conserves space, and makes production lines less complex.

Applications: It has a broad utility in packaging factories of large as well as small scales.

Corrugated Rotary Slotting Machines

Features: These types of machines are used for slitting purposes specifically designed for corrugated carton board. It cuts slits on the layered ply level of the carton board (e.g. 3 ply, 5 ply etc.) and other thickness levels.

Advantages: Cut mostly around the board type, and ability to cut different sizes and configurations of boards.

Applications: Very useful on the providers of boxes made from corrugated materials.

Explanation of Each Type

1. Manual Rotary Slotting Machines

These machines come with a low price tag and are the first in the slitting line of manual rotary crashing machines that can bridge sutures and slots. They do however, offer value for small volumes and production lines, but only after the operator changes dependencies for each job.

Example Use: Usage would be from local packing materials companies or start up companies working on a narrow budget low.

2. Semi-Automatic Rotary Slotting Machines

Semi automatic machines fall in the mid-range between automatic machines and manual machines models. They are semiautomatic because they have some level of automation for example motorized blade adjustment, but still some manual factor involved in the operation.

Example Use: Services will be provided to such medium scale packaging business who want to improve their efficiency.

3. Automatic Rotary Slotting Machines

These machines are the last of the types who come fully automated, working on standards and controlled parameters using PLCs. The machine comes fitted with a touch screen making it easy for the user to set it up, hence streamlining and enabling low engagement high speed productivity with rapid memory orders turning orders.

Example Use: Large productions requirements can use such machines, common in manufacturers of corrugated boxes and large scale factories.

4. Thin Blade Rotary Slotting Machines

Utilizing a thin blade technology provides smoother cuts and generates less dust in the course of production. This type of machine is ideal for producing boxes of top quality where the thickness of cardboard is of paramount importance.

Example Use: Packaging manufacturers seeking the best possible smooth edges and neat folds of the package.

5. Combined Rotary Slotting and Creasing Machines

With the slotting and creasing functions integrated, these machines enhance the production process and lower its costs. They are also compact and flexible, which perfectly fits the needs of factories where space is a constraint.

Example Use: Factories in need of integrated but inexpensive solutions.

6. Corrugated Rotary Slotting Machines

These machines are specially made for corrugated cardboard and operate on various thicknesses and ply levels. They are very versatile and indispensable for factories whose products vary in size of corrugated boxes.

Example Use: Industrial-scale packaging companies making boxes for different purposes and industries.

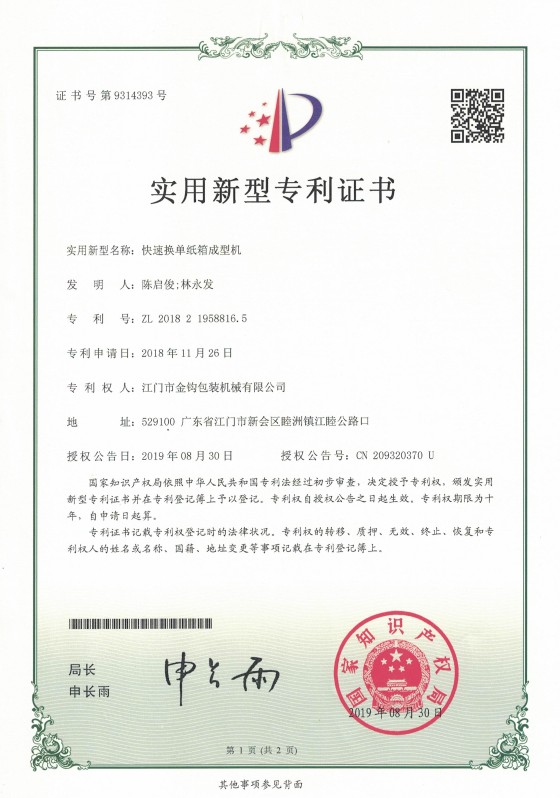

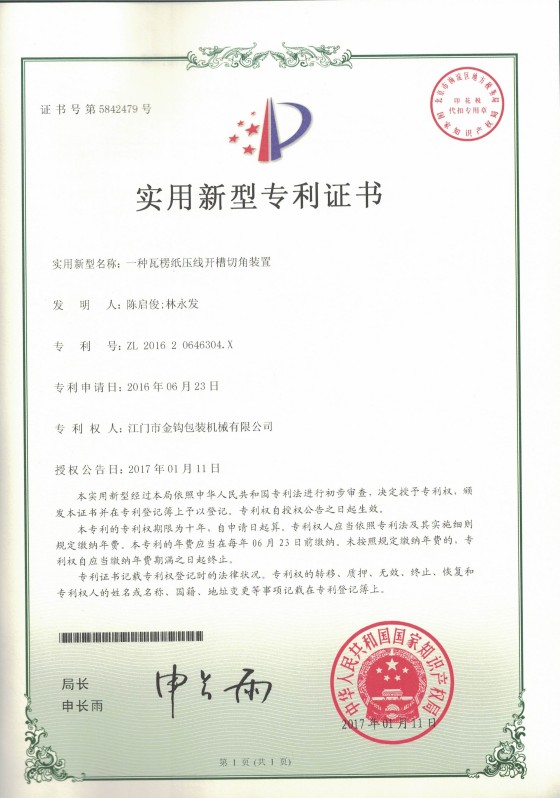

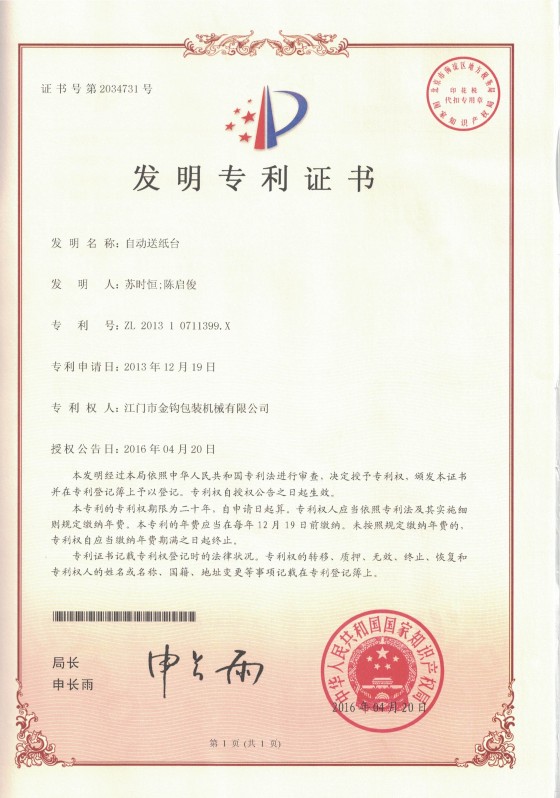

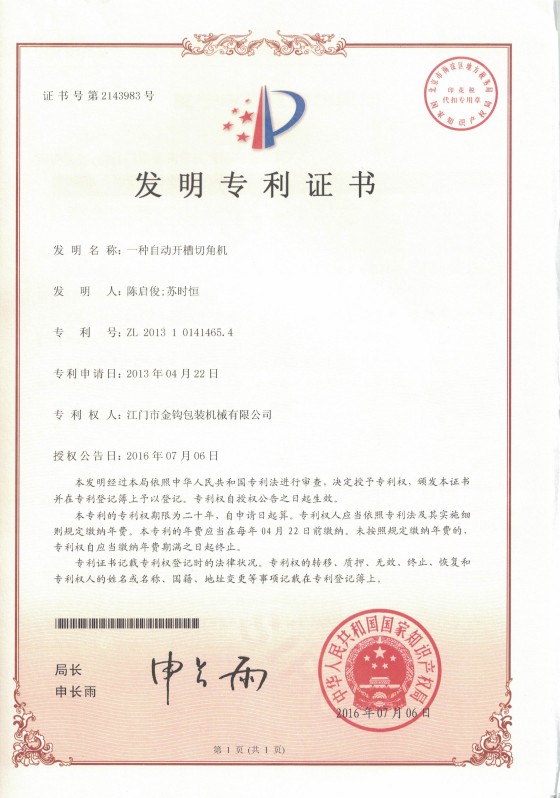

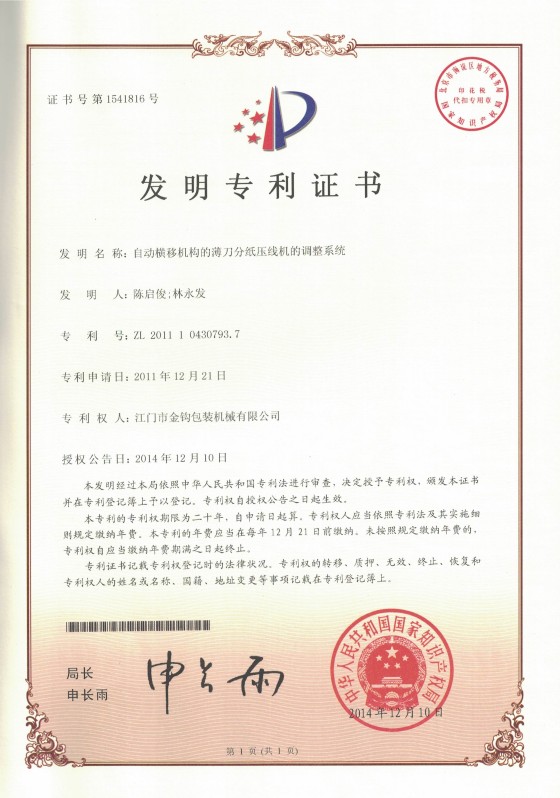

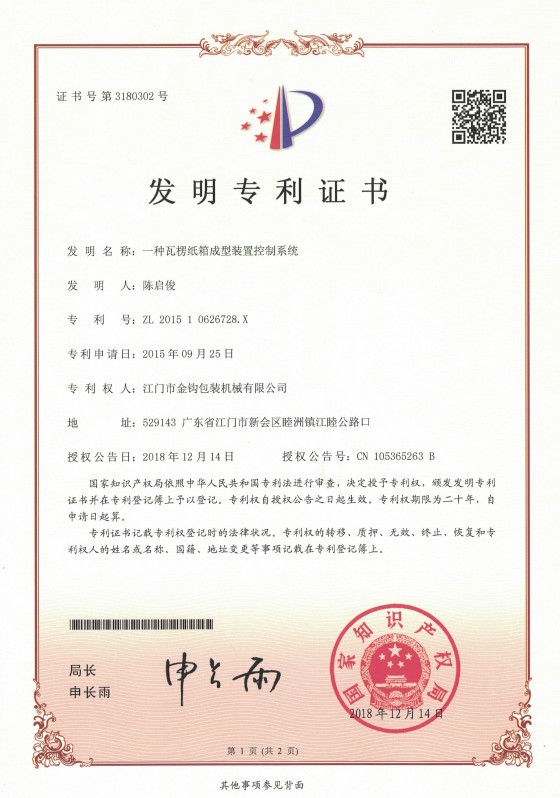

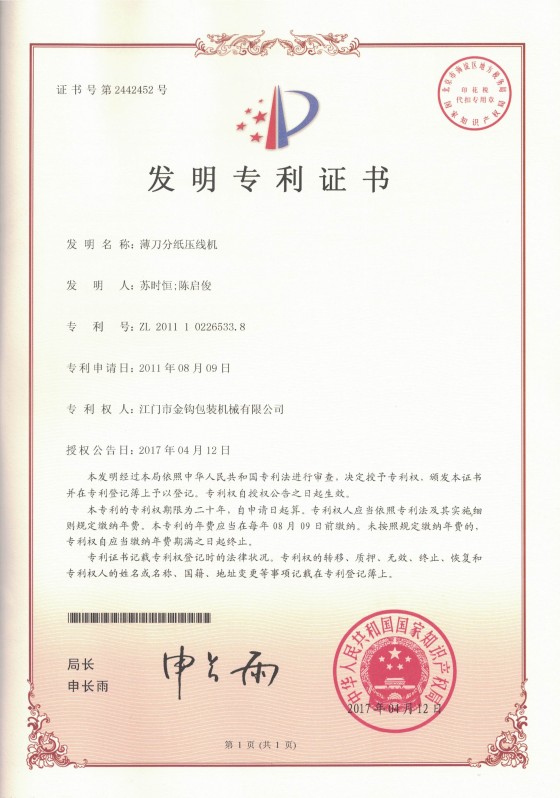

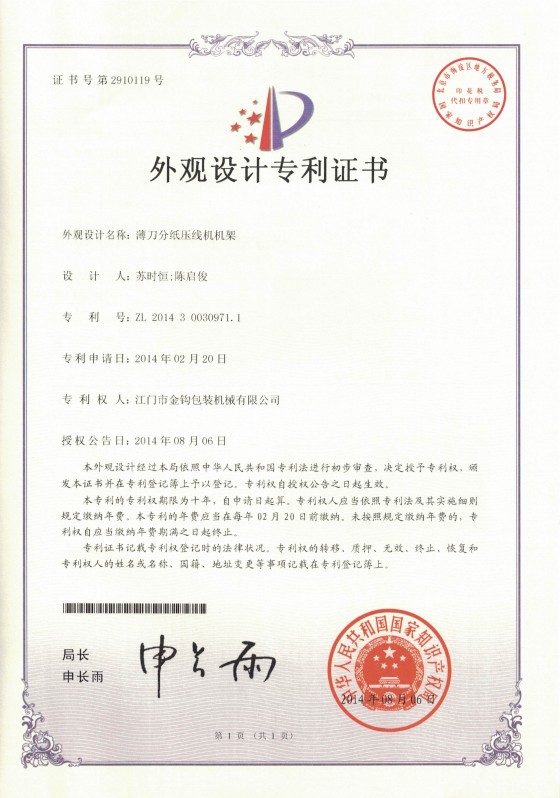

Jingou packaging machinery Co.,ltd

Jingou is a high-tech enterprise with forward thinking special designed,manufacturer of corrugated carton machine for small quantity orders .We had developed a very first auto thin slitter scorer machine which you can not find all over the world in 2009.And we keep working on developing functional box maker machine CK25 which earn many invention patents and utility model patents and passed CE certifications .Jingou machine had completed changed the low efficiency production mode of small quantity orders to meet the true needs of customers .