High-Precision Automatic Cardboard Box Forming Machine

Cardboard Box Forming Machine

-

+86-13702592807 WhatsApp

-

sales@jingoupack.com Email

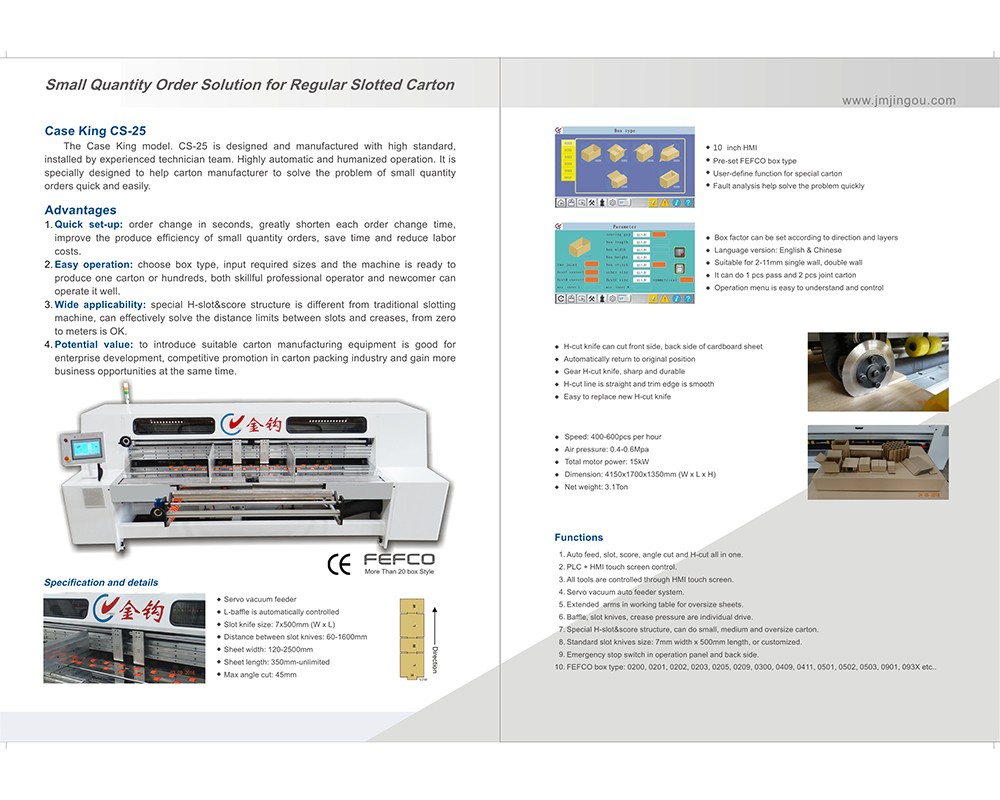

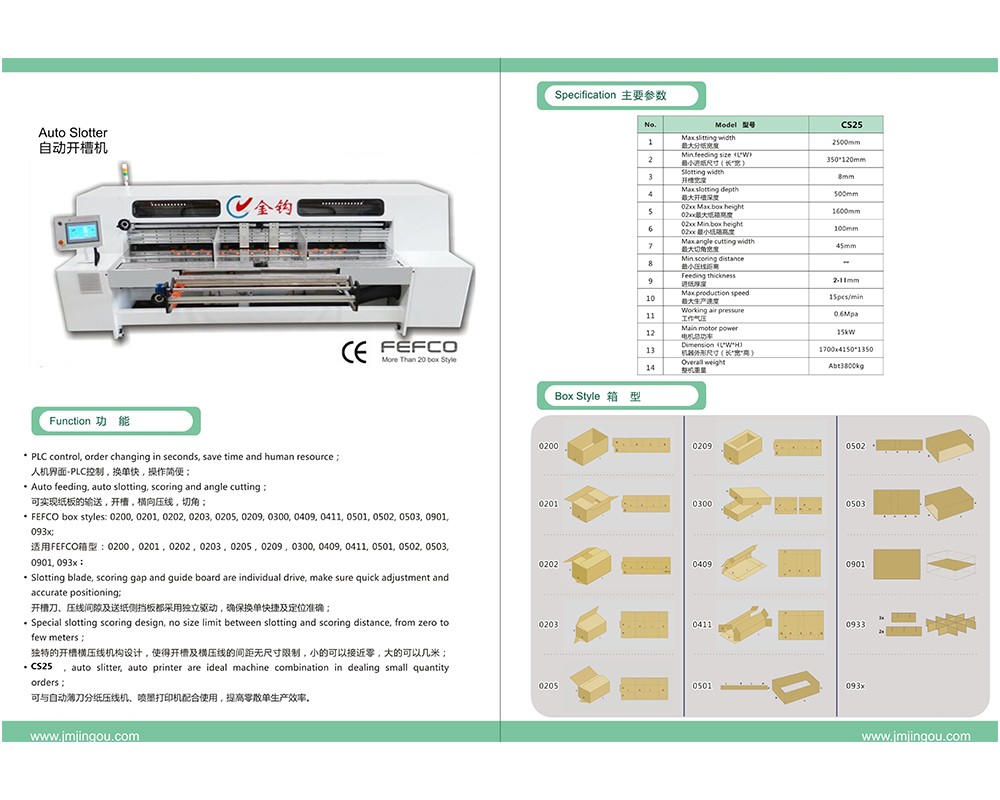

The Automatic cardboard box forming machine is a complete and modern device for serial production of boxes made from corrugated cardboard. Manufactured by a high class China cardboard box forming machine Manufacturer, it offers modern technology and simplicity in operation to achieve a better quality and quantity of boxes produced per time. Suitable for a range of applications including the packing of furniture, appliances or decorative boxes, the automatically carton box making Corrugated Box Making Machine is efficient, robust and versatile to different manufacturing requirements.

cardboard box forming machine Parameter

| Model | CS25 |

| Max.Feeding Size(W*L) | 2500mm*unLimited |

| Min.Feeding Size(W*L) | 120*350MM |

| Die-Cut Size | 140*190mm*lpcs |

| Slotting Width | 7mm |

| Max.slotting Depth | 500mm/400mm/300mm |

| 02xx Max.box Height | 1600mm/1800mm/2000mm |

| 02xx Min.box Height | 70mm |

| Max.angle Cutting Width | 45mm |

| Feeding Thickness | 2-11mm |

| Speed | 400-600pcs/h |

| Air Pressure | 0.3-0.6Mpa |

| Total Motor Power | Abt.15kW |

| Dimensuioin(W*L*H) | 4020*2050*1380mm |

| Overall Net Weight | Abt5000kg |

Advantages of Cardboard Box Forming Machine

Precision and Versatility:

Compatible with 3-ply and 5-ply corrugated cardboard.

A wide range of box structures can be accommodated such as H-slot, V-slot, die cutting and creasing.

Efforts Saving Automation:

PLC+HMI controlled, fully operable with minimal set up times (1-30 seconds).

Up to 300 box configurations may be stored in memory for efficient production changeovers.

Effective Output:

Maintained accuracy at production rates of up to 400 boxes/thour.

A variety of board thicknesses ranging from 2 to 11 mm are within its scope.

Ergonomic Design and Low Energy Costs:

Crafted from sturdy materials for effective functional performance.

Overall motor power 15kW which optimizes energy expenses.

Easy Interfacing and Operation:

Touch screen makes it simple for controls and extends usability to new operators.

Features aimed at rapid maintenance and resolutions of ad hoc situations.

Application of Cardboard Box Forming Machine

Corrugated Box Manufacturing:

Perfect for mass production of corrugated board boxes that may be used for packaging industrial goods, furniture, and other consumer products.

For Factories Manufacturing Cardboard Materials:

Very applicable for Carton Box Forming Machine Suppliers and factories requiring style variations in their packaging automatically.

Packaging tailored to the Customers Requirement:

Suitable for quick production of customized boxes and short runs of box production for variable manufacturing requirements.

Cardboard Box Forming Machine FAQs

Q1. What are the primary purposes of this automatic carton box making machine?

A1. The cardboard box forming machine is designed for slotting, creasing, die-cutting, and scoring; thus, it can produce boxes with the highest quality standards with less time and less effort.

Q2. Can this machine be used for low volume production?

A2. Yes, its memory storage capacity and simple operation allow it to be used in both large and low production runs.

Q3. What strategies does this machine use to address power consumption?

A3. One of the most outstanding features of this equipment is that it is power efficient, and specific power requirements can be optimized to achieve high work productivity.

Q4. What are the advantages of using a Chinese manufacturer for cardboard box forming machinery?

A4. Corrugated Box Machines manufactured in China accompany advanced technology, reliability, and high-quality at lower prices which are hard to find.

Q5. Describe the most basic types of boxes that this machine can create.

A5. Box types that can be supported include H-slot, V-slot, cross-score, die-cut boxes among others as this machine is highly adaptable for different packaging purposes.

Operational Guidelines for the Cardboard Box Forming Machine

During the pre-operation phase of the machine:

Verify that the Automatic Corrugated Box Making Machine is connected to the electrical network and air compressor.

Inspect the corrugated cardboard for any damage or deformation.

Program the Automatic Corrugated Box Making Machine parameters, including slotting width, depth of creasing and production speed, in the PLC control panel.

Steps Involved in the Operation:

Input of Dimensions for the Box: It is possible to use the touch interface or information from the machine's memory to enter the meaning of the boxes or part of the order based on its values.

Loading of the Material: Corrugated cardboard sheets are inserted into the feeding unit and it has to be ensured that they are properly loaded.

Starting the Cardboard Box Making Machine: At the beginning of the process, the button is pushed in order to commence machine operation. The system willbe responsible for cutting slots cutting, scoring assigning or die cutting them automaticaly.

Collection of the output: After completing the task, the cut out cardboard boxes are ejected for folding and further assembly.

Post Industrial Activities:Switch off the Corrugated Box Machine and unplug the electrical cord.

Take out residual material from the Carton Box Making Machine:Remove sharps and other working surfaces that are used for essential machine elements from the creasers, blades.

Maintenance of a Cardboard Box Forming Machine?

Daily Cleaning:

Every time you use the Cardboard Packaging Machine, ensure that all cardboard debris and dust generated during the use are cleaned from the machine.

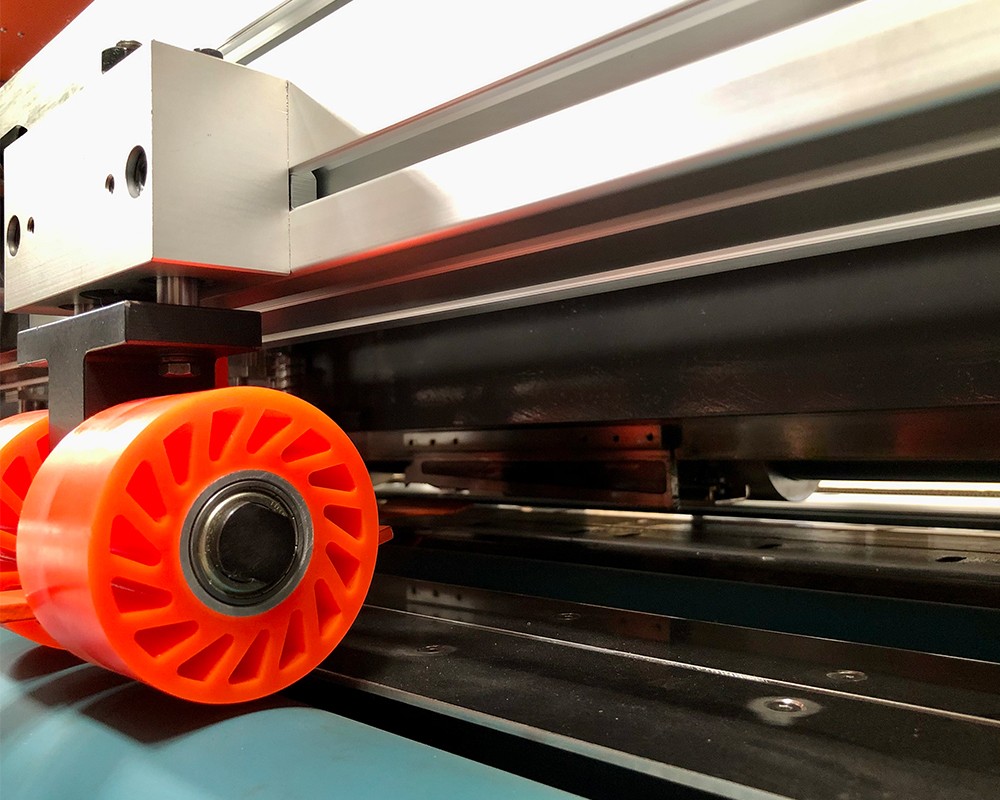

Wipe the Carton Box Machine parts such as the cutting blades, the creasing rollers, and the machine feeding system using a brush or there is/are compressed air.

Lubrication:

It is a good practice to oil bearings and other moving parts of the Corrugated Cardboard Machine such as gears and guides on a regular basis to avoid rapid wear and tear on such components.

Following the company’s instructions on oiling the Corrugated Box Manufacturing Machine is also important.

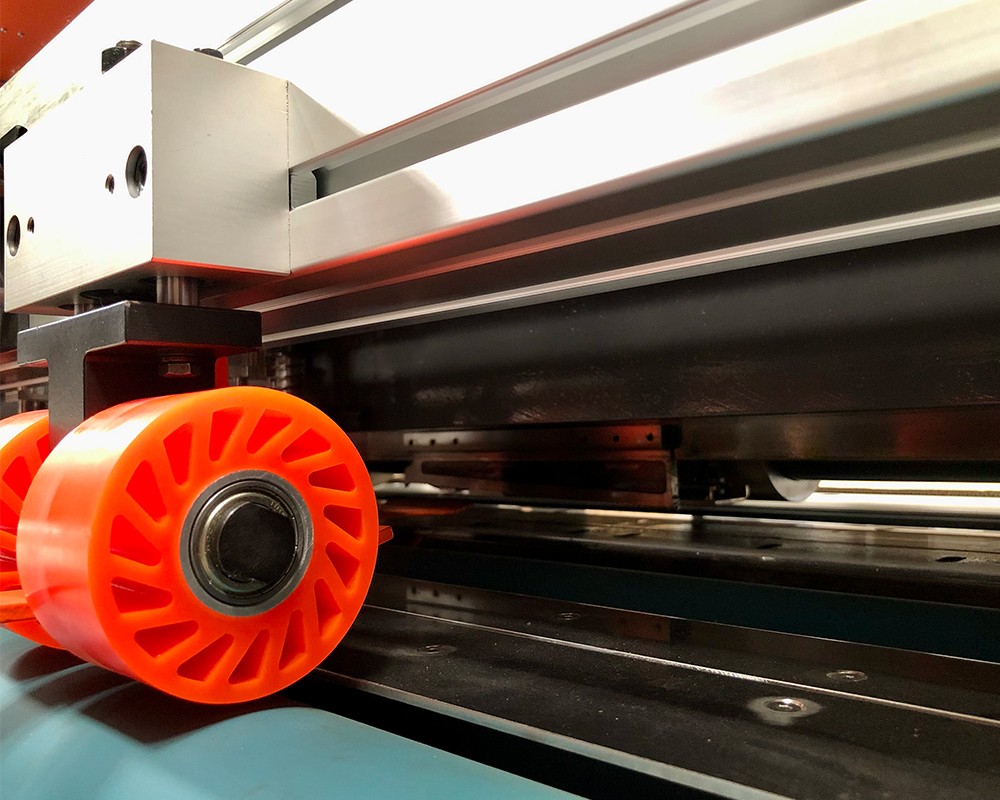

Blades and Rollers Maintenance:

It is essential to confirm the sharpness of the slotting blades and the die-cutting blades where necessary; these blades should be sharpened or replaced.

Adjust the position of the creasing rollers with regard to wear and tear or general misalignment where appropriate.

Electrical System Check:

All connections and wiring must be checked to see they are secured and in good condition.

Check whether the PLC system and the touchscreen respond smoothly and also whether it does so.

Periodic Calibration:

This procedure involves adjusting the parameters of the end devices to ensure the accuracy and repeatability of the boxes produced.

Air and Power Systems:

The air hoses and the compressor will be checked for any leaks.

A stable power system also is checked as it will prevent interruptions to the operator.

Different Types of Cardboard Box Forming Machines

Manual Cardboard Box Forming Machine:

Specifications: This is the simplest type, requiring setup and operating by hand. Best used for low-volume production use.

Uses: This type is useful in active proper or for factories with limited production lines.

Semi-automated card forming equipment:

Features: It features a combination of automation processes and manual work.

Applications: This is applicable in small and medium enterprises where moderate production is needed.

Completely automatic cardboard box forming equipment:

Features: Highest level of automation and control for extreme high output as there is a PLC and HMI feature.

Applications: Valid for large factories where high efficiency is needed and higher production is anticipated.

Machinery used for the molding of corrugated cardboard boxes:

Features: Targets corrugated cardboard which is highly sizeable material. Capable of handling various thicknesses (2-11 mm).

Applications: Most frequently and especially used by suppliers of Corrugated Box Maker Machine for making boxes out of corrugated cardboard) for packaging operations in industry.

All in one box forming device:

Features: Multiple operations slotting trans, board scoring and streamlining are combined in one single system.

Applications: Ideal for small to medium production where there is a need for cost and space economy.

Corrugated cardboard box forming machine that can be adjusted:

Features: These Cardboard Corrugator Machines are usually built based on client specifications for design or production of distinct boxes.

Applications: Suitable for businesses that require certain types of packagings.

Jingou packaging machinery Co.,ltd

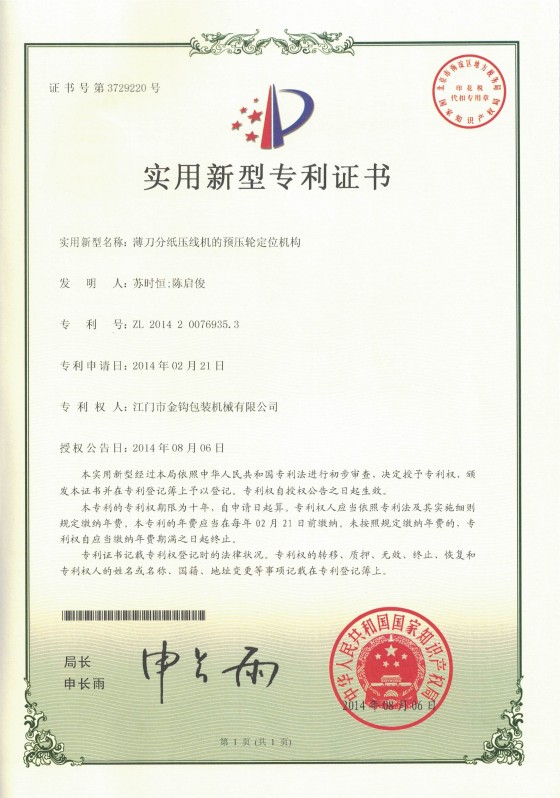

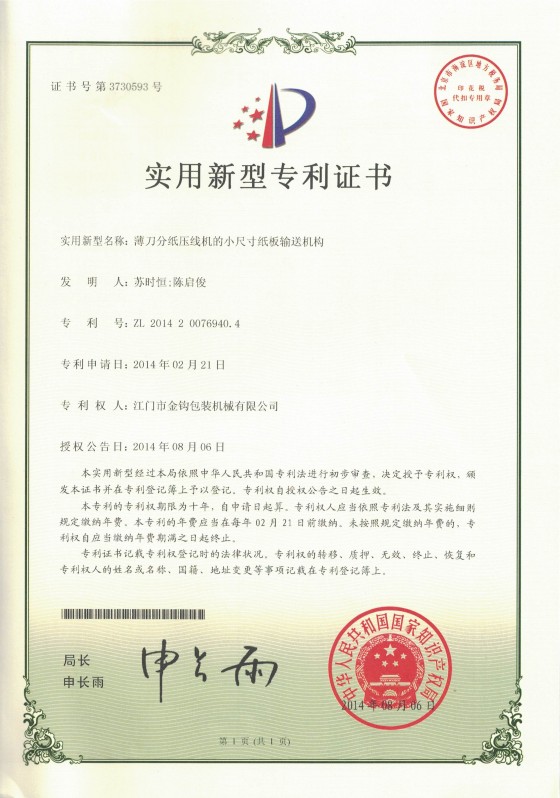

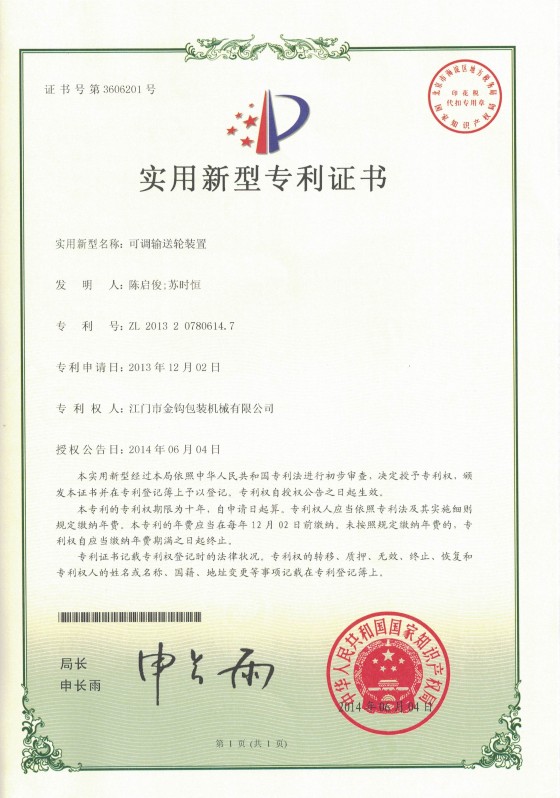

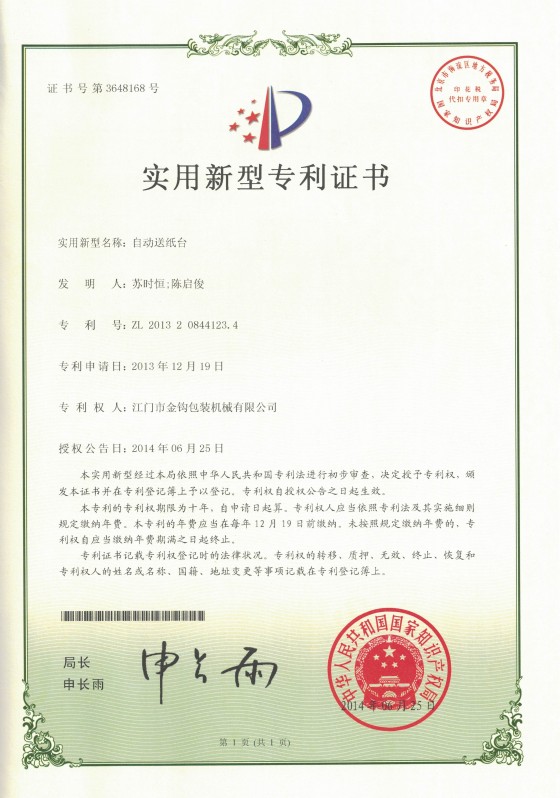

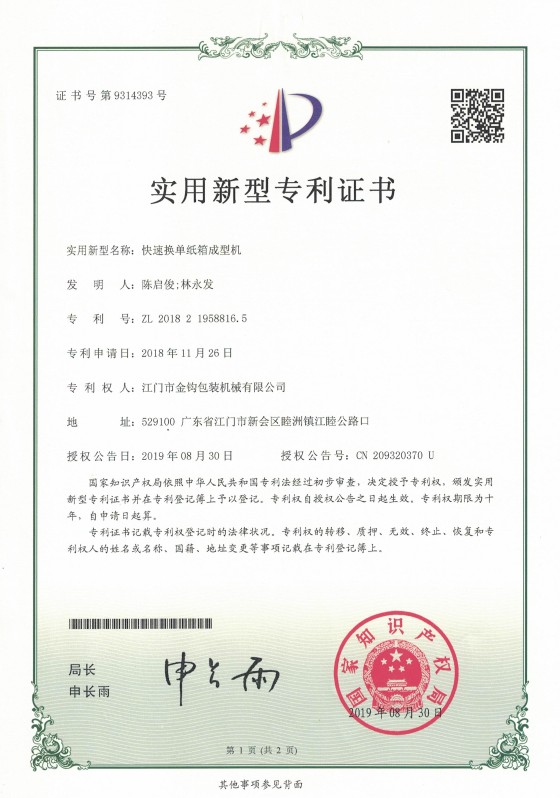

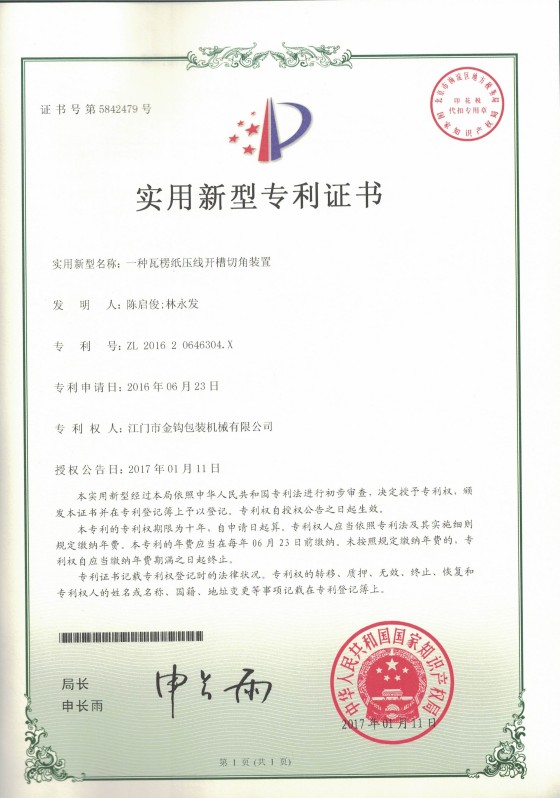

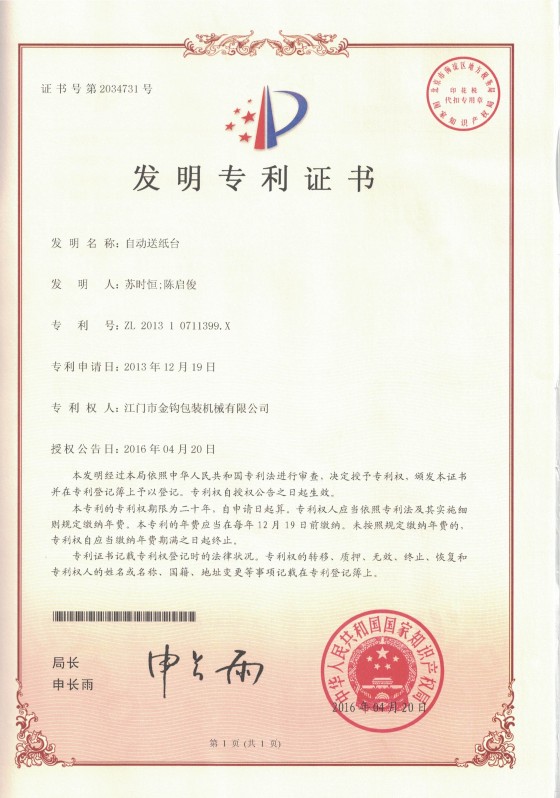

Jingou is a high-tech enterprise with forward thinking special designed,manufacturer of corrugated carton machine for small quantity orders .We had developed a very first auto thin slitter scorer machine which you can not find all over the world in 2009.And we keep working on developing functional box maker machine CK25 which earn many invention patents and utility model patents and passed CE certifications .Jingou machine had completed changed the low efficiency production mode of small quantity orders to meet the true needs of customers .