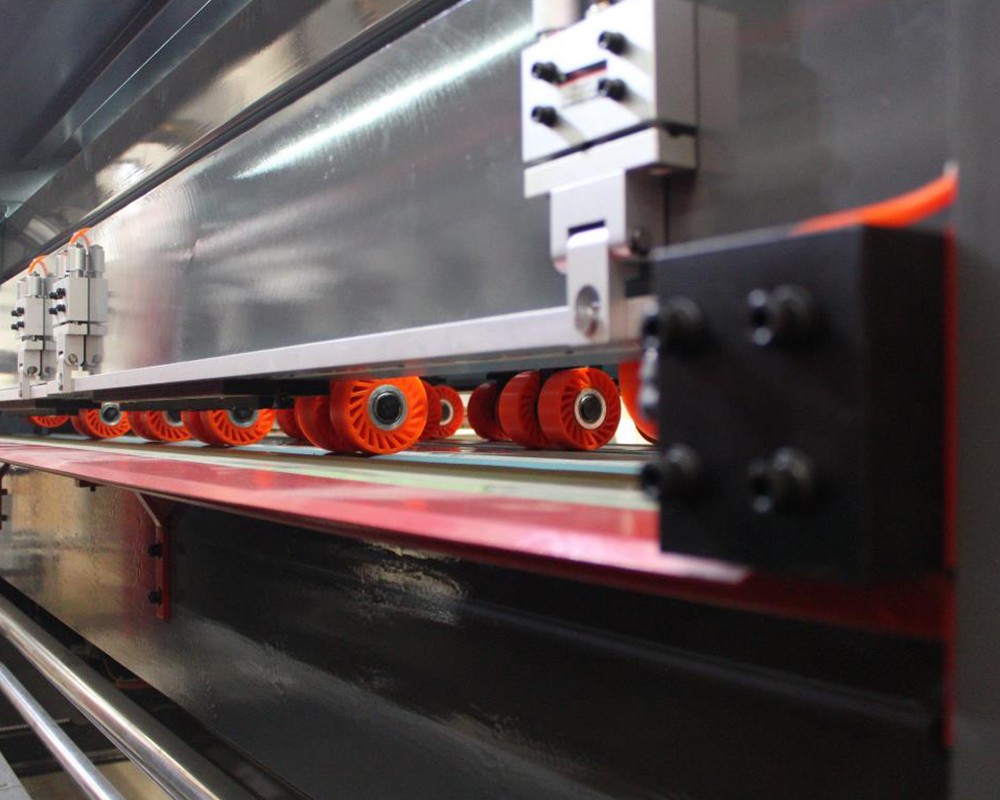

Cs25 Fully Automatic Corrugated Box Making Machine

Carton Forming Machine

-

+86-13702592807 WhatsApp

-

sales@jingoupack.com Email

The CK Fully Automatic Corrugated Cardboard Box Making Machine is ideal for the production of fluted boxes. Equipped with a highly detailed design, high economies of scale will even help the enterprise breathe. Another sustained economic profitability are the automated carton box making process such as the Batch Sizes Ordering, Cutting, Scoring and Die Cutting processes. One of the strongest competitive advantages of this advanced version of the market is that it cuts lead times in the manufacturing of end-use cases.

Corrugated Cardboard Machine Parameter

| Model | CK25 |

| Max.feeding Size(W*L) | 2500mm*unlimited |

| Min.feeding Size(W*L) | 120*350mm |

| Die-Cut Size(W*L) | 140*700mmx2pcs |

| Slotting Width | 7mm |

| Max.slotting Depth | 500mm |

| 02xx Max.box Height | 1600mm |

| 02xx Min.box Height | 100mm |

| Max.angle Cutting Width | 45mm |

| Feedng Thickness | 2-11mm |

| Speed | 400-600pcs/h |

| Air Pressure | 0.3-0.6Mpa |

| Total Motor Power | Abt15kw |

| Dimension(W*L*H ) | 4050*700*2000mm |

| Overall Net Weight | Abt8000kg |

Advantages of Corrugated Cardboard Machine

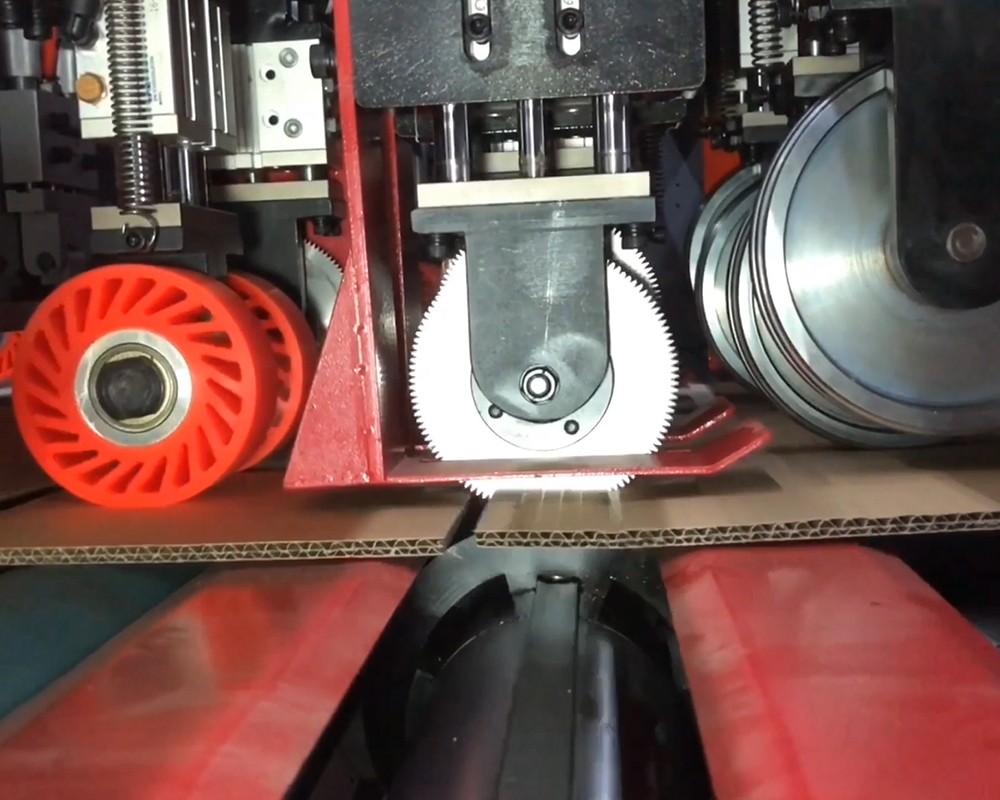

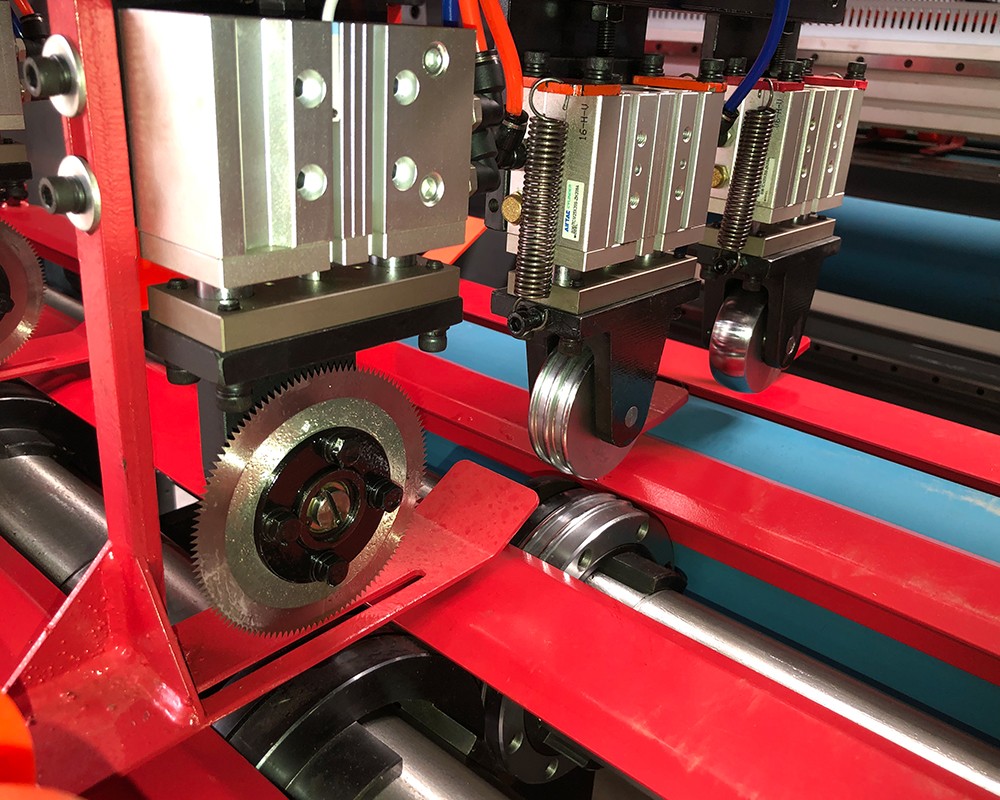

Precision Engineering: High precision cutting and scoring will tools will ensure that every product have the same quality as the former.

Automated Workflow: Fully automated workflows and processes will decrease the amount of labor required and the time taken to deliver the product.

Flexible Design: Allows for multiple box designs and sizes for wider packaging options.

Durable Construction: Made from strong material and substance to support reliability and stability of the Corrugated Cardboard Making Machine.

User-Friendly Interface: Intuitive touchscreen control panel for effective operations during the Corrugated Cardboard Machine's use and changes during the operation.

Energy Efficiency: This Corrugator Machine is highly efficient due to the low power consumption needed while operating at full potential at any time.

Application of Corrugated Cardboard Machine

Industrial Packaging: Perfect for use in manufacturing boxes used during transportation of electronic, automobile and machinery products.

Retail Packaging: Good in the packaging of boxes designed for consumer products across e-commerce and retail sectors.

Food and Beverage: Appropriate for making boxes for food delivery, storage and transportation.

Custom Packaging Solutions: Can manage special box design for particular markets.

Corrugated Cardboard Machine FAQs

What is the output rate of CK Fully Automatic Corrugated Cardboard Machine?

Depending on the design of the box and material thickness, the Corrugated Box Manufacturing Machine is capable of producing 400-600 boxes in one hour.

Is it applicable to any type of corrugated cardboard?

Yes, the Corrugated Box Maker Machine is compatible with any grade of corrugated cardboard which has a thickness of 2mm to 11mm.

How difficult is to change the box design from one to another?

The transitions between different designs in this case are simple due to the PLC system which makes it easy to make changes.

What would be the recommended maintenance for the Corrugated Carton Making Machine in question?

Optimal performance requires periodic cleaning, lubrication of movable components and adequate blade grinding.

Do I have the ability to change the design of the automatic corrugated box machine?

Yes, such designs can be modified to include additional parts for production as well as for printing and scoring.

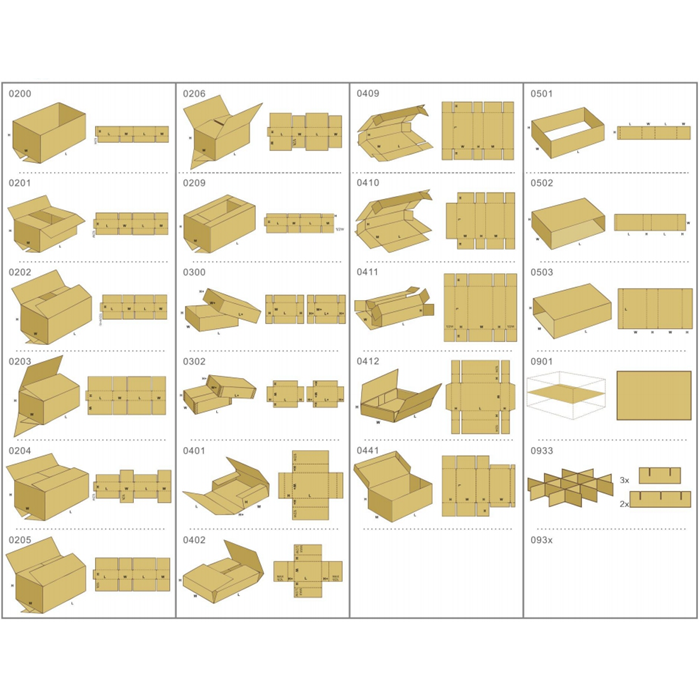

Corrugated Cardboard Machine can Make Box-shaped

Corrugated Cardboard Machine can also Produce theFollowing Box Types

★00301,0452,0453,0911,0300

★0458,0302

★0900,0902,0903,0901

★0930,0931,0932,093,0935,0933

★Define one time pass:0214,0228,0229,0230,0231,0403,0413,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

★Define two time pass:0208,0210,0212,0400,0420,0456,0921,0941,0943,0944

★Combnation box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

Operational Processes for a Corrugated Cardboard Machine

Preparation:

Confirm that the automatic corrugated box packing machine is securely held and powered on.

Insert the corrugated board materials into the feeding unit without distortions.

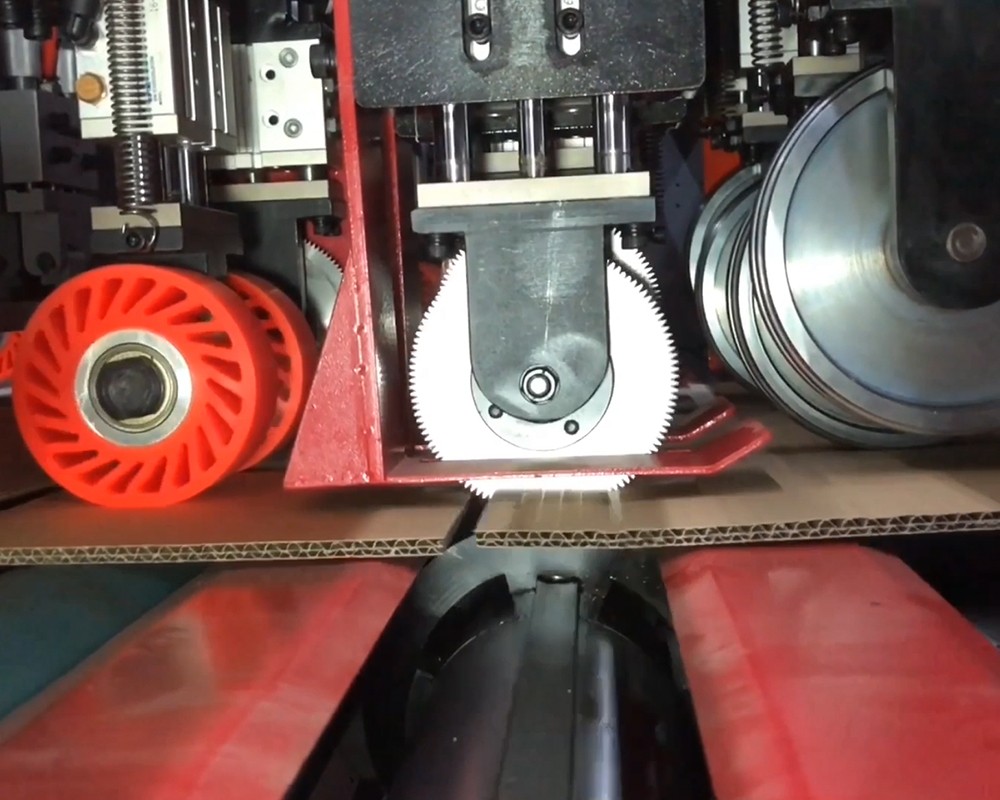

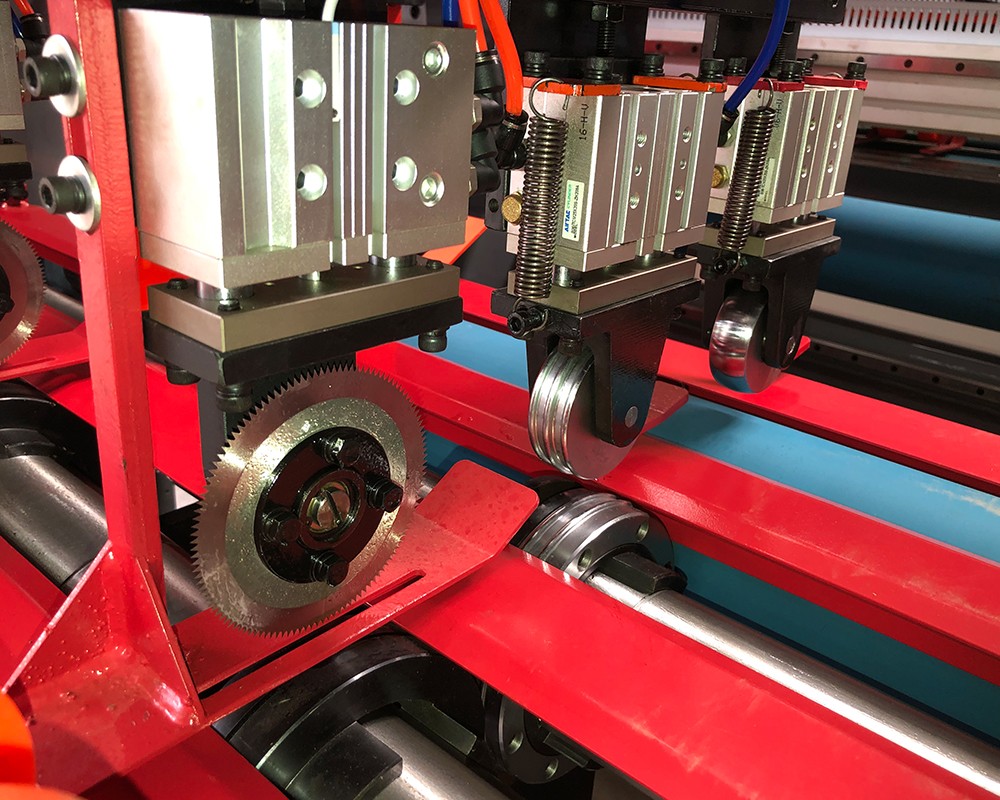

Examine the setting of the cutting/creasing/slitting tools.

System Configuration:

Power the automatic corrugated box plant and go to the HMI PLC control.

Specify the required body dimensions to be constructed such as width, height and slot location.

Choose the pre-set styles of boxes.

Start Operation:

Carry out a test run in order to confirm the parameter is operational.

Engage into production, by hitting the ‘Start’ button which is found on the control panel.

Feeding, creasing, cutting, and slitting cycles shall be sequentially achieved depending on how the automatic corrugated box stitching machine was programmed.

Monitoring:

Follow the procedure at the back of the comment to make sure things are functioning as desired.

If any outputs are out of control within three parameters, do not bring any adjustments.

Post-Operation:

Once the production process is completed, shut the machine down.

Dispose off the waste, and leave the room in a tidy condition.

Safely keep unused parts and materials accumulated for future use.

Automatic gluing machine corrugated box Maintenance Methods

Daily Maintenance:

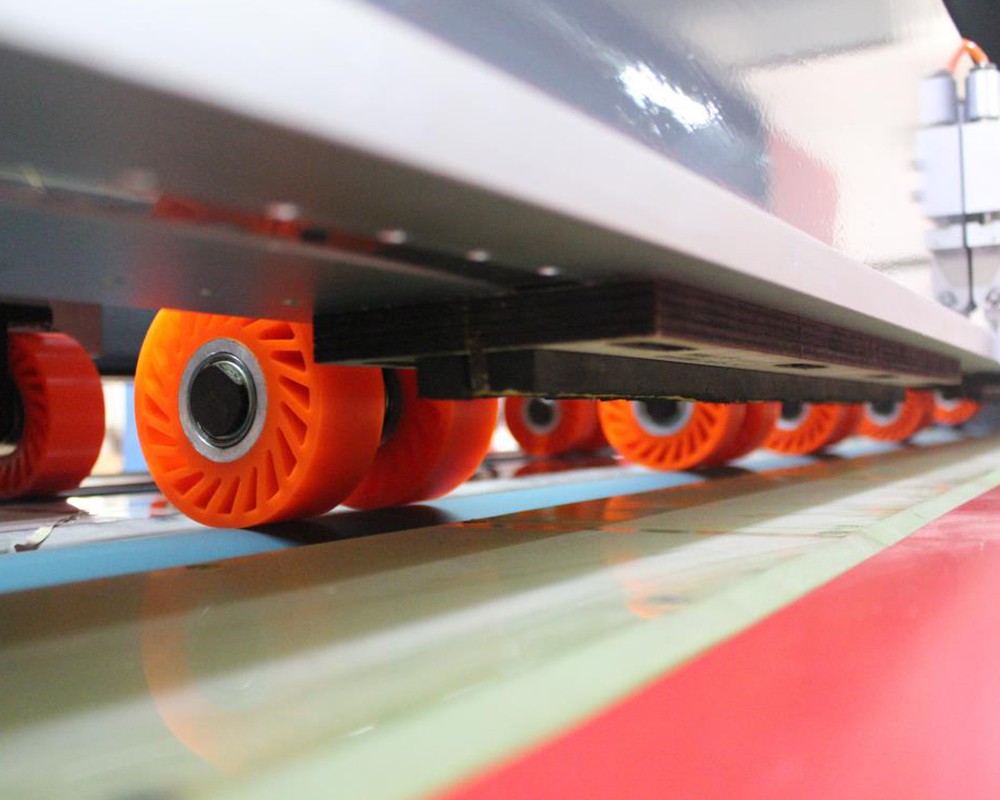

Machine surfaces, rollers, and the feeding unit should be cleaned from dust and remains of the working materials.

Check for the blades, creasers, and die-cutting tools whether there are any signs of wear and tear.

Make sure that the moving parts such as chains, bearings and gears are appropriately lubricated.

Weekly Maintenance:

Feeding rollers need to be oriented properly and adjusted when required.

Controls and Sensors’ control system of the automatic pasting machine for corrugated boxes needs to be checked for accurate working.

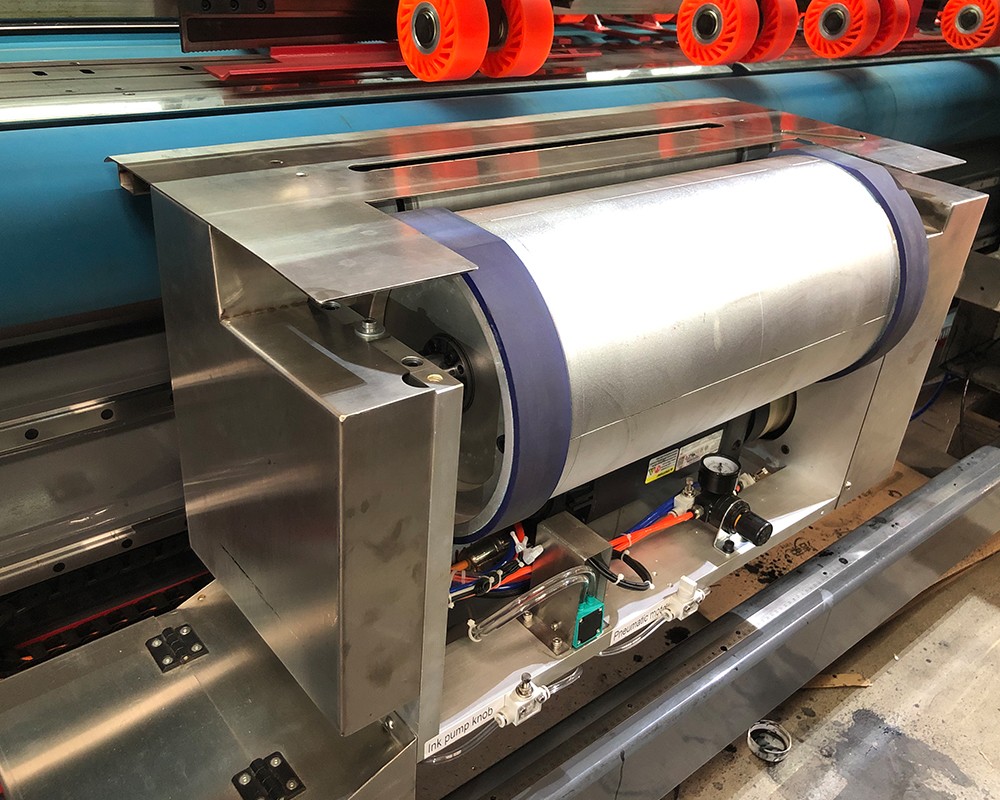

Ensure the pneumatic components are in good working order and also check the air pressure.

Monthly Maintenance:

All the electrical connections should be checked at regular intervals. Damaged wiring should be replaced immediately.

Blades should be replaced where appropriate for cutting and creasing efficiently.

Screws bolts and other fasteners should be checked for tightness.

Annual Maintenance:

Belts, rollers and gears that have been worn out must be changed.

Using a control panel installing the software on correct version should be calibrated.

Perform a full system check to ensure everything is safe and secure.

General Maintenance Tips:

The Lubrication oil must be of good quality, corrugated automatic machine cleaning material should be optimal.

There should be no water in the surroundings of corrugated board cutting machine to avoid its rusting.

Recommended spare parts should be used as per manufacturer’s recommendation.

Types of Corrugated Cardboard Machines

The Manual Corrugated Cardboard Machines:

Created for small-scale factories.

Blank needs to be manually placed in the corrugated board making machine before each production run.

Low price and can be used in simple boxes.

Semi-Automatic Corrugated Box Making Machines:

Manual feeding and automatic cutting and creasing production processes are combined.

Medium-sized businesses can benefit from it.

In terms of machine concepts, it is comparatively inexpensive and adaptable for many box designs.

Fully Automatic Corrugated Box Making Machines:

Automatic feeders, cutters, creasers, and set die-cutters are all included.

Great for mediums that go through generation with little human interference.

Perfect for mass production.

Corrugated Box Slotting and Creasing Machines:

Slotting and creasing boards made of corrugated board with specialized cutting tools.

High precision can be obtained and the above is used with other machines.

Die-Cutting Corrugated Cardboard Machines:

Mainly concerned with die-cutting boxes into complex forms.

Excellent for intricate shapes used in attractive packaging solutions.

Corrugated Box Erector Machines:

Fold and bond the boxes automatically making box erectors suitable for handling boxes.

Automated packaging lines commonly utilize them.

Corrugated Cardboard Flexo Printing Machines:

This two-in-one machine allows printers to print so as to produce for branding and other additional features.

Mainly aimed at manufacturers intending to produce and print great products.

Corrugator Machines (Making Cardboard Sheets):

Makes corrugated sheets out of kraft paper.

The process serves as the preliminary stage of the cardboard making process.

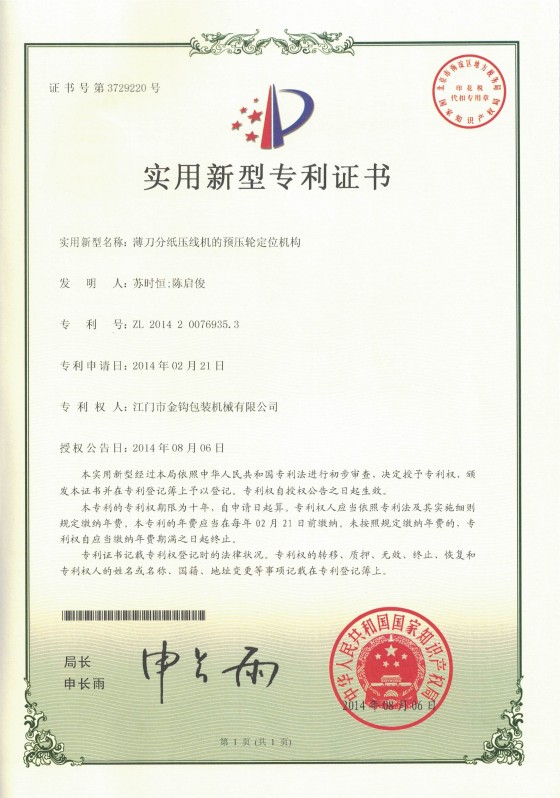

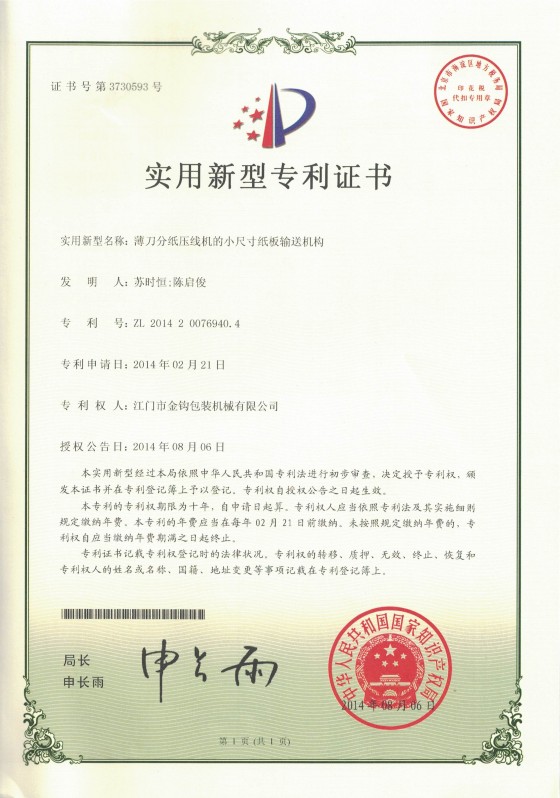

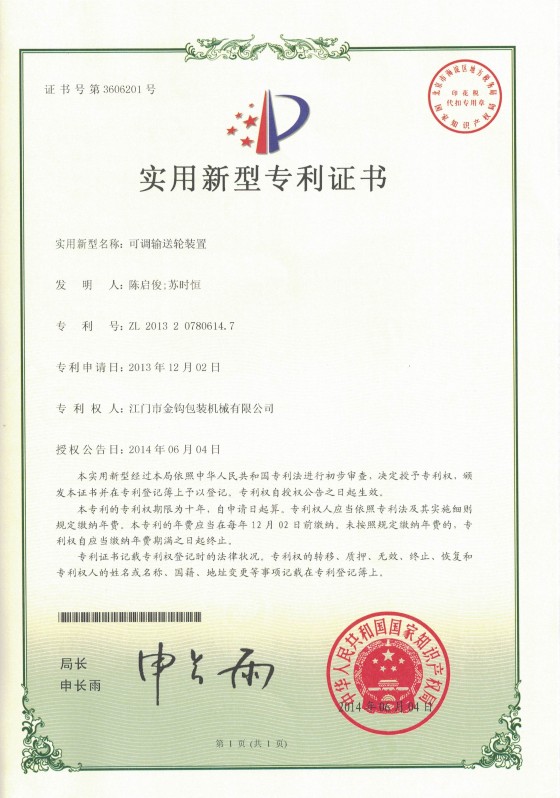

Jingou packaging machinery Co.,ltd

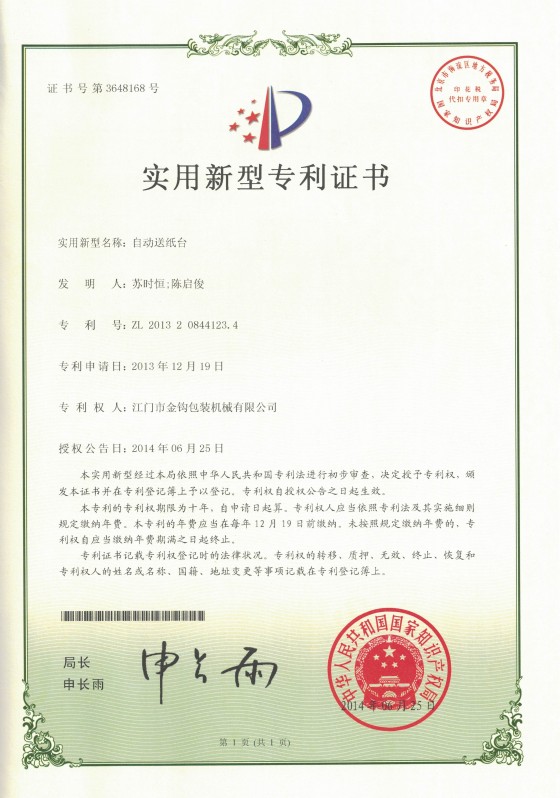

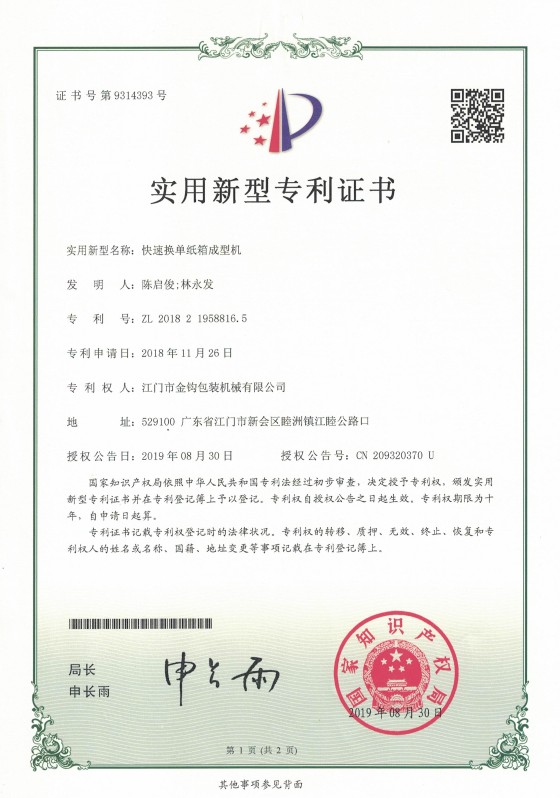

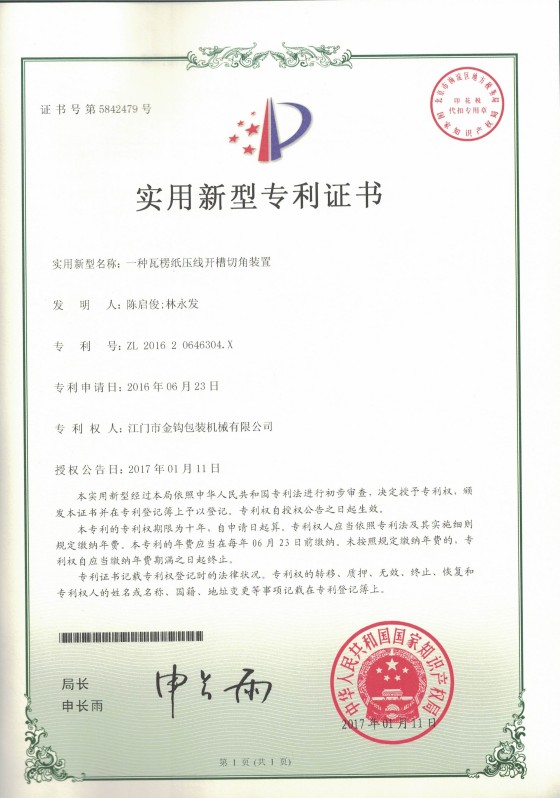

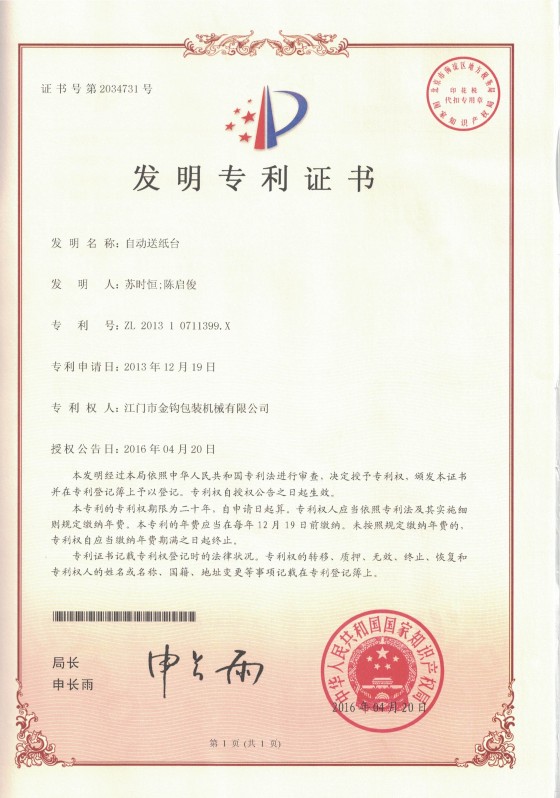

Jingou is a high-tech enterprise with forward thinking special designed,manufacturer of corrugated carton machine for small quantity orders .We had developed a very first auto thin slitter scorer machine which you can not find all over the world in 2009.And we keep working on developing functional box maker machine CK25 which earn many invention patents and utility model patents and passed CE certifications .Jingou machine had completed changed the low efficiency production mode of small quantity orders to meet the true needs of customers .